Hydraulic Rotating Pulverizer

Hydraulic Rotating Pulverizer is widely used in the demolition of factory buildings, beams and columns, civil houses and other buildings, steel bar recovery, concrete crushing, etc. due to its features of no vibration, low dust, low noise, high efficiency and low crushing cost. Its working efficiency is two to three times that of a hydraulic breaker.

We can offer the OEM/ODM services of excavators attachments. The product can be customized according to your personalized requirements. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Specification – 360° Rotating hydraulic pulverizer

The following are the technical parameters of the Rotating hydraulic pulverize.

| Unit | JT-06 | JT-08 | JT-08S | JT-10 | |

|---|---|---|---|---|---|

| Weight | kg | 1450 | 2000 | 2700 | 3300 |

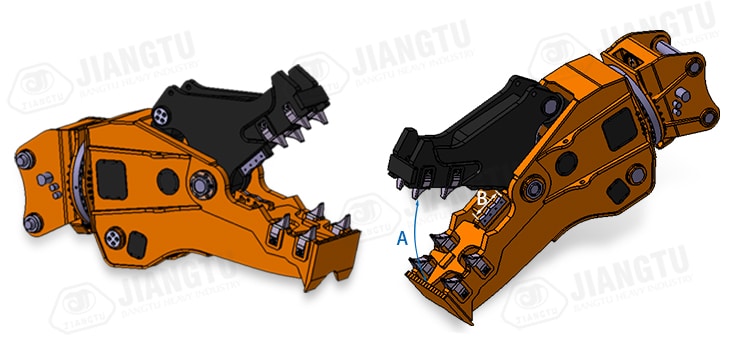

| A Max Open | mm | 700 | 780 | 880 | 930 |

| Cutting force | ton | 185 | 220 | 300 | 330 |

| Crushing force | ton | 60 | 70 | 100 | 120 |

| Working Pressure | bar | 350 | 350 | 350 | 350 |

| B-Cutter Length | mm | 180 | 220 | 260 | 260 |

| Max.Flow when rotation | L/min | 28 | 28 | 28 | 28 |

| Open/Close | S | 1.5/3 | 2/3 | 2/3 | 2.5/3.5 |

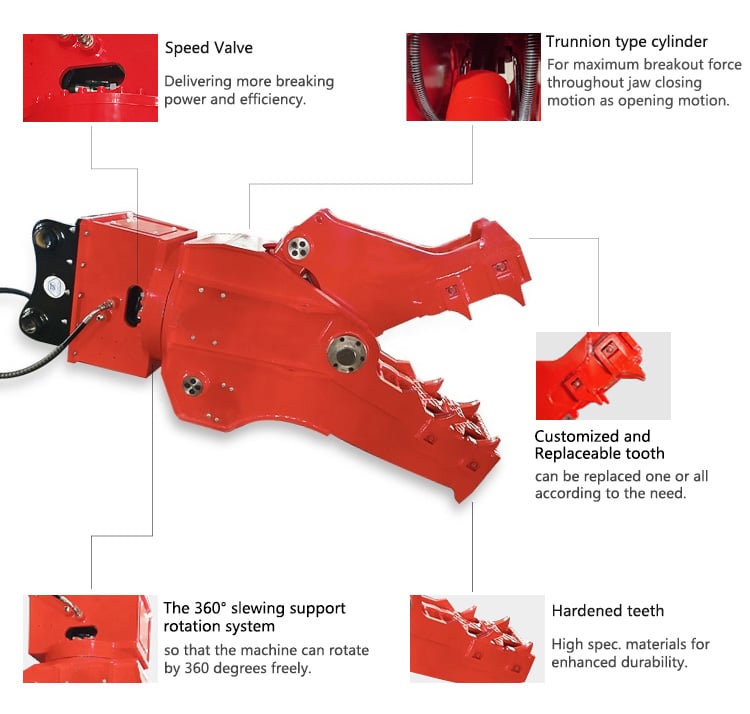

Main Advantages of Hydraulic Rotating Pulverizer

Meanwhile, Jiangtu hydraulic Rotating pulverizers still retain the characteristics and advantages of ordinary hydraulic pulverizers.

Video & Image

Certificate

Through 10 years of digging in research and development, JiangTu Company achieved more than 20 patents such as invent/design patent successively and received CE, ISO, and SGS certificates from 2012 to 2021 and now started a new chapter to explore the global market.

ABOUT JIANGTU

Yantai Jiangtu Mechanical Equipment Company is a leading manufacturer of excavator attachments in China. All products’ quality is strictly under control from processing to delivery. The company has got ISO 9001, CE Certifications, and Technical Patents successively by continuous innovation and improvement. Our products have been sold to widely domestic and overseas customers and long-term partnerships have been developed.