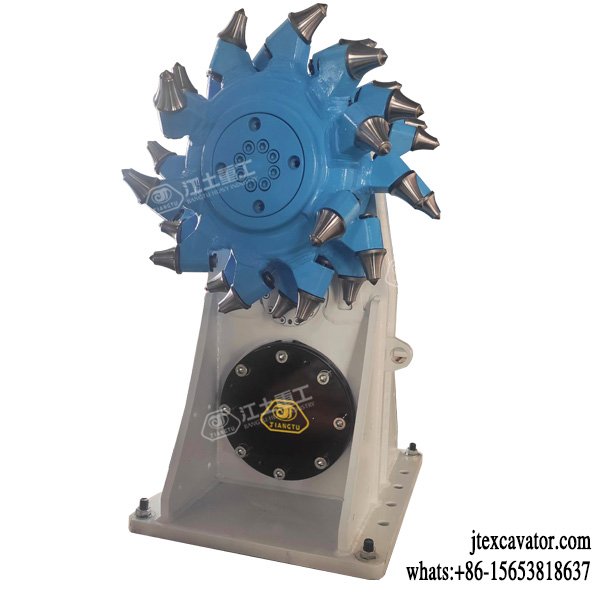

Drum Cutter

The JIANGTU drum cutter for excavator is a hydraulic attachment mounted on the front boom of an excavator, specifically designed for excavation, shaping, and trenching of rock, concrete, and frozen soil. This drum cutter boasts high efficiency, fast rotation speed, quiet operation, and minimal dust. It features high precision, low noise low vibration, simple structure, ease of use, and the ability to backfill waste materials. It is ideal for construction environments with limited noise or vibration and can replace traditional hydraulic breakers or blasting methods.

Main Advantages of JIANGTU Drum Cutter:

- High-Performance Hydraulic Drive

- Durable Construction

- Low Vibration & Noise

- Accurate control of the excavation surface

- Simple structure, easy to use, and relatively low price

- Precision and Versatility

- Easy Maintenance

What Is a Drum Cutter for Excavators?

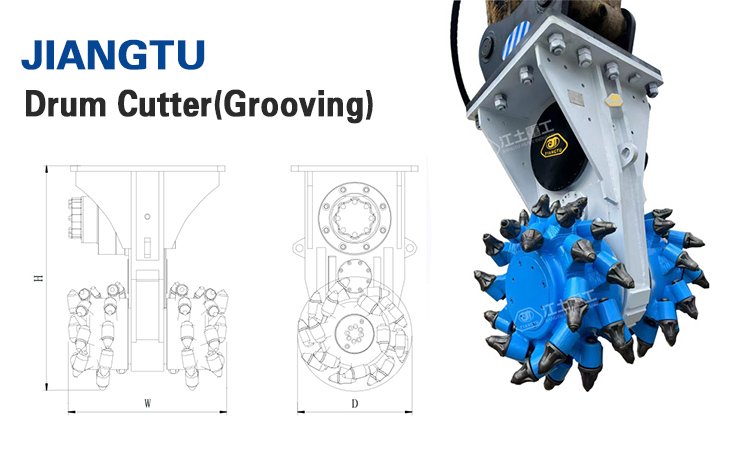

A drum cutter (also known as a rotary drum cutter or rock wheel) is a hydraulic attachment equipped with two rotating drums fitted with wear-resistant picks. Driven by the excavator’s hydroulic system, it achieves precise, low-vibration cutting of rock concrete, or soil through continuous grinding. The cutter’s hydraulic motor drives the drums in opposite directions, breaking down materials through continuous contact. Unlike percussive tools, drum cutters remove material by grinding, producing a smoother finish and reducing stress on the carrier machine.

Specification – Drum Cutter

The following are the technical parameters of the Drum Cutter.

Category | Unit | JT-04 | JT-06 | JT-08 | JT-10 |

|---|---|---|---|---|---|

Engine Displacement | ml/r | 398 | 1340 | 2099 | 4198 |

Speed Range | r.min | 0-90 | 0-130 | 0-85 | 0-140 |

Max Flow Rate | L/min | 47 | 174 | 280 | 580 |

Rated Power | Mpa | 28 | 25 | 25 | 30 |

Max Pressure | Mpa | 40 | 30 | 35 | 45 |

Max Torque | N.m | 3200 | 5200 | 12800 | 23500 |

Max Power | kw | 40 | 45 | 70 | 110 |

Number of Cutting Heads | pcs | 32 | 44-56 | 56 | 76 |

Weight | kg | 210 | 600 | 1650 | 2000 |

Excavator Weight | ton | 3—10 | 10—15 | 20-25 | 30-40 |

Cutter Head Type | 20-22 | 22-24 | 30 | 30-35 |

Each model supports various cutting heads and pick options for different job conditions.

Main Advantages of JIANGTU Drum Cutter

1、High-Performance Hydraulic Drive: Optimized torque and speed deliver consistent cuting performance across various rock types.

2、Durable Construction: Rugged housing made of wear-resistant steel (HARDOX optional) ensures long service life even in abrasive conditions.

3、Low Vibration & Noise: Reduce vibration and protect the environment: it can replace blasting construction, has low vibration and noise, and can better protect the environment.

4、Accurate control of the excavation surface: It can better solve the problems of over-excavation and underexcavation, accurately trim the excavation contour and help reduce costs.

5、Simple structure, easy to use, and relatively low price: It can be installed on any existing excavator without special suporting equipment. Compared with tunnels, shields and other machinery, the equipment is cheap.

6、Precision and Versatility: Multiple drum sizes and pick configurations fit excavators from 3–40 tons.

7、Easy Maintenance: Simple structure and accessible parts simplify inspection and repair.

Key Applications of Drum Cutters on Excavators

Rock Excavation and Trenching

Quickly and precisly excavate hard or soft rock, create trenches for utilities, or shape tunnel profiles.

Demolition and Concrete Profiling

Ideal for removing reinforced concrete, surface scaling, and controlled demolition where accuracy matters.

Underground, Underwater, and Frozen Ground Operations

Engineered for challenging environments—can operat underwater (up to 8-10 m) or in frozen ground(minus 40 degrees Celsius).

Urban and Sensitive Areas

Thanks to their low vibration and quiet operation, they are safe to use near hospitals, schools, and residential zones.

Through 10 years of digging in research and development, JiangTu Company achieved more than 20 patents such as invent/design patent successively and received CE, ISO, and SGS certificates from 2012 to 2021 and now started a new chapter to explore the global market.

How to Choose the Right Drum Cutter for Your Excavator

1. Carrier Compatibility

- Match cuter size and hydraulic power with your excavator’s class.

- Example: 10–15 t excavators → JT06 model; 20–25t → JT08.

2. Hydraulic Flow and Pressure

Ensure your excavator can provide sufficient oil flow and pressure.

3. Material Type

Select drum and picks according to rock hardnes or material type.

4. Environmental Requirements

Low-noise and water-resistant options are ideal for urban or underwater work.

5. Service and Support

Choose a brand with reliable after-sales service and spare parts availability.