Vibratory Pile Driver

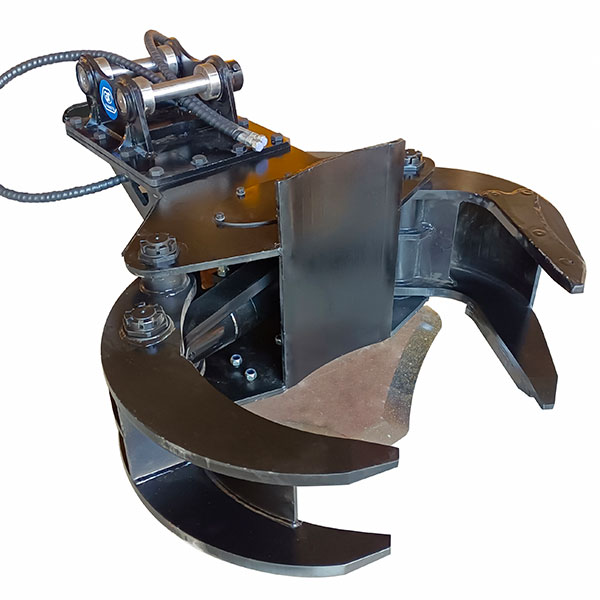

JIANGTU vibratory pile driver for excavator is a hydraulic attachment designed to be mounted directly on an excavator for fast and efficient pile driving and extraction. by generating high-frequency vertical vibration, this excavator-mounted vibratory pile driver significantly reduces soil resistance, allowing piles to be installed or removed quickly with minimal noise and ground disturbance.

Widely used for sheet pile driver applications, pipe piles, H-beams, and various foundation projects, this equipment has become an essential solution for modern infrastructure, marine, and urban construction.

Application: Sheet pile installation, Pipe piles and H-beams, Marine and port construction, Solar and infrastructure projects, Urban construction sites

We can offer the OEM/ODM services of excavators attachments. The product can be customized according to your personalized requirements. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Excavator Vibratory Pile Driver Specification

| Model | Unit | JT150 | JT250 | JT330 | JT350 | JT450 |

|---|---|---|---|---|---|---|

| Eccentric moment | Nm | 22 | 40 | 50 | 65 | 85 |

| Frequency | Rpm | 2500 | 2800 | 2800 | 2800 | 2800 |

| Excitation Force | Ton | 15.1 | 36 | 45 | 58 | 75 |

| Weight of main body | Kg | 1300 | 2800 | 3000 | 3300 | 3300 |

| Operating Pressure of oil system | Bar | 220-320 | 280-330 | 280-330 | 280-330 | 280-330 |

| Flow Demand for Hydraulic oil system | Lpm | 110-160 | 150-240 | 168-250 | 210-260 | 255-280 |

| Excavator | Ton | 15-18 | 18-25 | 24-30 | 31-35 | 36-50 |

| Piling Height of standard am | M | 5 | 6 | 6-7 | 7-8 | 8-9 |

| Max pile length | M | — | 9 | 13 | 16 | 18 |

The piling extension arm is a set of excavator front-end working devices specially designed and manufactured to expand the piling range of the excavator. The JIANGTU piling extension arm is made of Q345B steel, which has good strength and rigidity. The shaft sleeve is made of 45#+20# steel, and 40Cr village sleeve is inlaid inside..

JIANGTU Piling Arm Parameters

| Models | Unit | JT20T | JT30T | JT35T | JT40T | JT45T |

|---|---|---|---|---|---|---|

| Totallength | mm | 13000 | 14000 | 15000 | 16000 | 18000 |

| Weight | kg | 3500 | 4000 | 4500 | 5000 | 5500 |

| Height | mm | 11000 | 12000 | 13000 | 14000 | 16000 |

| Total height of loading | mm | 2950 | 3210 | 3210 | 3420 | 3420 |

Accessories

Features of JIANGTU Vibratory Pile Driver

Engineered for high performance, durability, and efficiency in demanding piling applications.

1. Heavy-Duty Drive Turntable

Manufactured from high-strength alloy materials, the drive turntable delivers exceptional wear resistance, stability, and load capacity. Designed to withstand high torque and intense impact forces, it ensures reliable performance during continuous piling operations.

2. High-Torque Hydraulic Rotary Motor

Powered by a robust hydraulic motor, the system provides large starting torque, fast response, and high efficiency, making it ideal for high-intensity and long-duration piling projects.

3. Reinforced Vice Arm

Built from high-strength alloy steel, the vice arm offers excellent hardness and impact resistance, significantly increasing working load capacity. Customizable designs allow optimal adaptation to different jobsit requirements, improving overall productivity.

4. Imported Hydraulic Vibration Motor

Equipped with an inclined-shaft axial piston motor, this vibration system delivers low-speed, high-torque output, high efficiency, low noise, and precise control. Its reliable design ensures easy maintenance and wide application compatibility.

5. Precision Hydraulic Clamping System

The fixture utilizes advanced hydraulic principles and a custom pressure-holding valve to deliver a stable and consistent clamping force. Clamping jaws can be customized for various pile types and construction scenarios, ensuring secure and efficient operation.

6. High-Performance Shock Absorption

Premium rubber damping blocks effectively reduce vibration and noise transmitted to the excavator, enhancing operator comfort and protecting the machine. The modular design allows quick replacement and easy maintenance.

7. Optimized Gearbox Design

A unique ventilation structure improves lubrication and heat dissipation, enhancing system efficiency and cooling performance. This results in smoother operation, longer service life, and enhanced piling quality.

8. Detachable Flip Axis

The removable flip-axis design simplifies servicing and maintenance while improving the equipment’s versatility and operational flexibility across different working conditions.

Product Images & Video

What Is A Vibratory Pile Driver For Excavator?

A vibratory pile driver, also known as a vibro hammer for excavator, is a hydraulic pile driving device that use rotating eccentric weight to generate vertical vibration force. When mounted on an excavator,, it utilizes the excavator’s hydraulic system to perform both pile driving and pile extraction operations. Inside the JIANGTU vibratory hammer, eccentric weights rotate at high speed to create continuous vertical vibration.. this vibration temporarily reduces friction between the pile and surrounding soil by loosening the soil structure, allowing efficient pile penetration or extraction.

Certificate

Through 10 years of digging in research and development, JiangTu Company achieved more than 20 patents such as invent/design patent successively and received CE, ISO, and SGS certificates from 2012 to 2021 and now started a new chapter to explore the global market.

FAQ

1. What types of piles can be installed?

Sheet piles, steel pipe piles, H-beams, I-beams, timber piles.

2. Is pile extraction possible?

Yes, the vibratory pile driver for excavator supports both driving and extraction.

3. What excavator size is required?

Suitable for excavators from 15 tons up to 50 tons and above.

4. Is it suitable for urban construction?

Absolutely. Low noise and controlled vibration make it ideal for city projects.

5. Does it require an external power unit?

No. The system operates directly from the excavator’s hydraulic system.

Vibratory Pile Driver vs Impact Pile Hammer

For projects requiring efficiency, environmental compliance, and precision, vibratory pile drivers offer clear advantages.

| Feature | Vibratory Pile Driver | Impact Pile Hammer |

|---|---|---|

| Noise Level | Low | Very High |

| Ground Vibration | Controlled | High |

| Installation Speed | Fast | Moderate |

| Urban Suitability | Excellent | Limited |

| Precision | High | Lower |

| Pile Extraction | Strong | Limited |