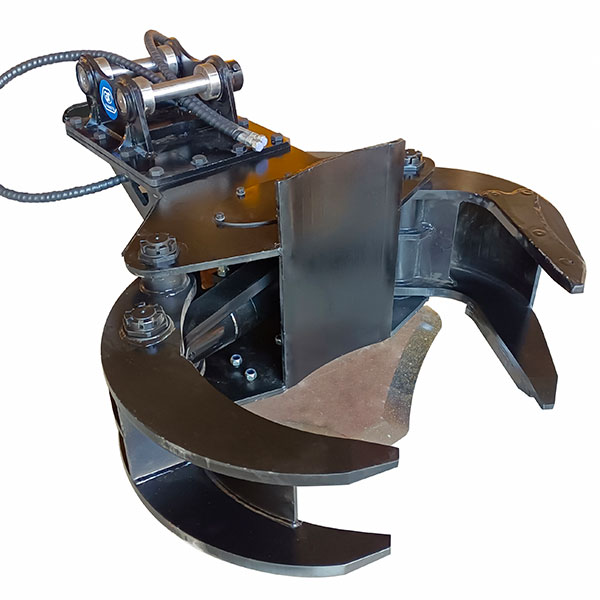

Twin-Ram Tilt Coupler

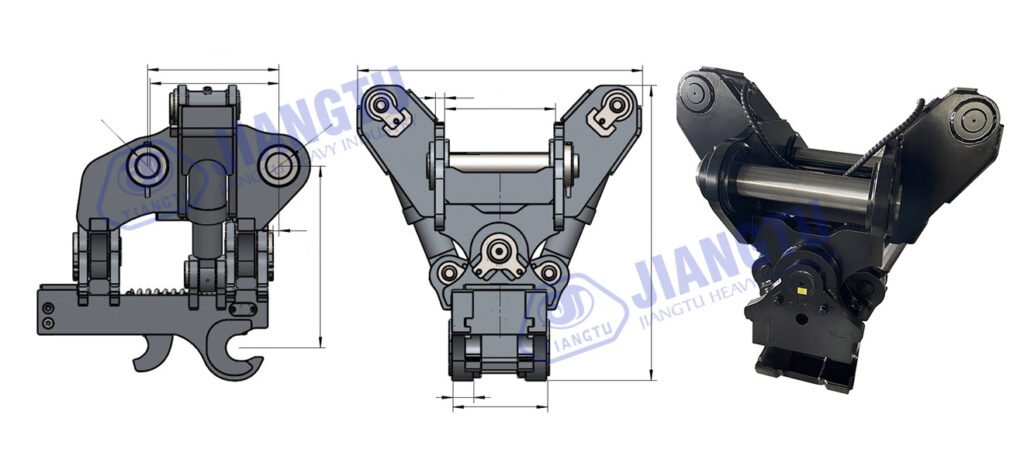

The JIANGTU Twin-Ram Tilt Coupler, also known as a Ram Tilt Hitch or Ram Tilting Coupler,, is a robust hydraulic attachment designed to provide powerful side-to-side tilt for excavator buckets and tools.. By using dual hydraulic rams, the Ram Tilt system delivers smooth, stable, and highly controlled tilting performance without the need to reposition the excavator.

This ram tilt coupler is widely used in earthmoving, grading, trenching, and infrastructure projects where accuracy, efficiency, and durability are critical.

Features of Twin-Ram Tilt Coupler

We can offer the OEM/ODM services of excavators attachments. The product can be customized according to your personalized requirements. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Twin-Ram Tilt Coupler Specification

| Category/Model | Unit | JT-08S | JT-10 | JT-14 | JT-17 |

|---|---|---|---|---|---|

| Excavator | Ton | 22-25 | 28-36 | 35-42 | 40-52 |

| Pin Diameter | mm | 90 | 90/100 | 100/110 | 110/120 |

| Tilt Angle | ° | ±45° | ±45° | ±45° | ±45° |

| Flow | LPM | >20 | >20 | >20 | >20 |

| Working Pressure | MPa | ≤35 | ≤35 | ≤35 | ≤35 |

| Max.Tilt Torque when 35MPa | kn.m | 65000 | 65000 | 85000 | 100000 |

| Lifting Point Capacity | Ton | 5 | 5 | 8 | 10 |

| Net Weight | kg | 1000 | 1100 | 1220 | 1430 |

Low-Profile Ram Tilting Coupler for Maximum Digging Efficiency

The Jiangtu TwinTilt features an industry-leading low-profile design, minimizing offset and preserving maximum breakout force.. This allows the excavator to maintain optimal digging geometry and productivity. A protected hydraulic cylinder layout shields key components from damage while keeping inspection and maintenance simple—an essential advantage for long-term jobsite reliability.

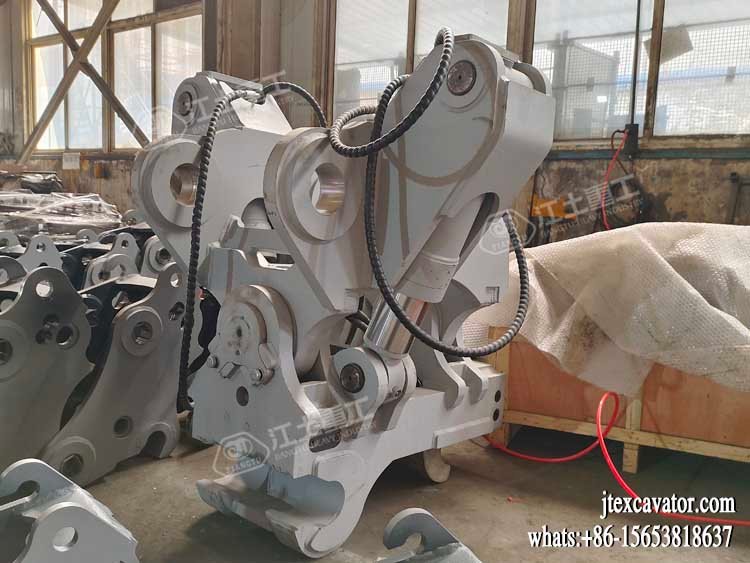

Built from Q690 High-Strength Steel – Certified to Global Standards

Manufactured from Q690 high-strength steel, the Jiangtu TwinTilt Ram Tilting Hitch is fully reinforced at all critical stress points.. With fewer moving parts than rotary systems, the structure is exceptionally robust and easy to maintain.

The ram tilt coupler complies with major international standards, including:

- AS 13031:2023

- EN 474

- ISO Standards

Its simplified actuator system allows faster inspection and servicing, helping contractors reduce downtime and save thousands of operating hours over the product’s life.

Features of Twin-Ram Tilt Coupler

Typical Applications of the Ram Tilt Coupler

The twin ram tilt hitch is especially well-suited for large-scale projects where durability, stability, and power are essential.

Product Images & Video

Certificate

Through 10 years of digging in research and development, JiangTu Company achieved more than 20 patents such as invent/design patent successively and received CE, ISO, and SGS certificates from 2012 to 2021 and now started a new chapter to explore the global market.

What Is a Twin-Ram Tilt Coupler?

A Twin-Ram Tilt Coupler is a hydraulic ram tilting hitch installed between the excavator dipper arm and the attachment. In addition to fast attachment changes, it allows the attachment to tilt left and right—typically up to ±45°—while maintaining strong breakout force and stabilityy.Unlike rotary tilt systems, Ram Tilting Hitches rely on heavy-duty hydraulic cylinders rather than complex rotary actuators. This makes the system simpler, more durable, and better suited for high-load and long-cycle construction work.

Twin-Ram Tilt Coupler vs Rotary Tilt Coupler

| Feature | Twin-Ram Tilt Coupler | Rotary Tilt Coupler |

|---|---|---|

| Tilt Mechanism | Hydraulic rams | Rotary actuator |

| Structural Complexity | Simple & robust | More complex |

| Maintenance | Low | Higher |

| Load Capacity | High | Medium |

| Cost Efficiency | Excellent | Higher cost |

For contractors prioritizing durability, simplicity, and cost-effective performance, ram tilting couplers are often the preferred choice

How to Choose the Right Ram Tilt Coupler

- Match the excavator operating weight to ensure stability and performance

- Check hydraulic flow and pressure compatibility

- Confirm attachment interface standards

- Evaluate jobsite conditions and duty cycle requirements

- Our team can help you select the most suitable twin ram tilt hitch for your excavator and application.

What is the difference between a Ram Tilt Hitch and a rotary tilt coupler?

A Ram Tilt Hitch uses hydraulic cylinders for tilting, offering a simpler and more robust design compared to rotary systems.

What tilt angle does a ram tilting coupler provide?

Most models offer up to ±45° of tilt, with custom configurations available.

Is the Twin-Ram Tilt Coupler suitable for heavy-duty work?

Yes. The twin-ram structure is designed for high-load, continuous operation.

Does the Ram Tilt system require additional hydraulics?

No. It operates using the excavator’s existing auxiliary hydraulic circuit.