What Is Hydraulic Pulverizer?

The hydraulic pulverizer is one of the attachments for excavator. It can break concrete blocks, columns, etc…and then cut and collect the steel bars inside.

Hydraulic pulverizer is widely used in the demolition of buildings, factory beams and columns, houses and other constructions, steel bar recycling, concrete crushing and other working conditions, due to their characteristics of no vibration, low dust, low noise, high efficiency, and low crushing cost. Its working efficiency is two to three times that of the hydraulic breaker hammer.

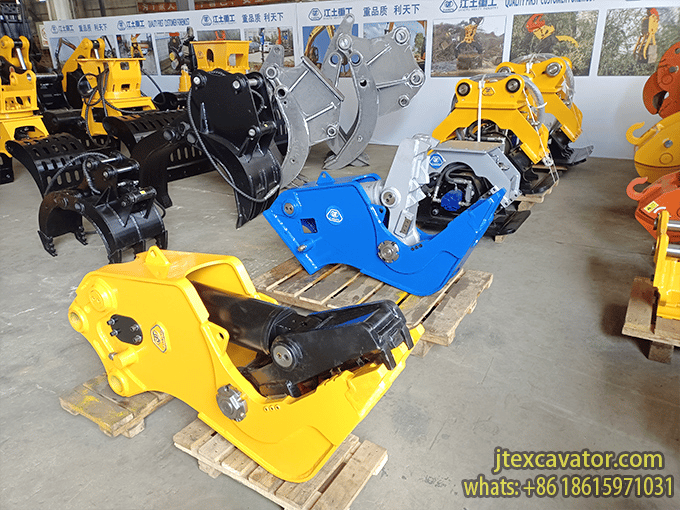

JIANGTU Demolition Pulverizers are designed for concrete reduction. It is ideal for breaking out concrete from fixed structures, pulverizing concrete, separating different materials for recycling, and cutting reinforced rods and small steel profiles.

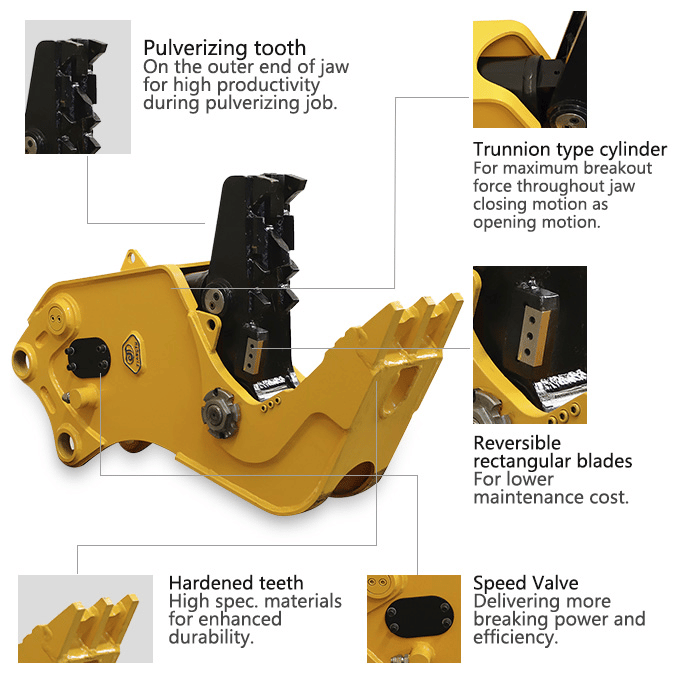

Jiangtu hydraulic pulverizer is composed of the main body, hydraulic cylinder, movable jaw and fixed jaw. The movable jaw and fixed jaw include crushing teeth and blades. The fixed jaw is located in the front of the pulverizer, and there are crushing teeth and blades in sequence from the outside to the inside. Hydraulic pulverizer can crush concrete blocks with high hardness and large volume, and the crushing effect is good.

The special shape of the jaws of Jiangtu hydraulic pulverizer is designed to firmly hold the concrete block, wedge and crush it, so it can be crushed quickly. Small occlusal gap, flexible operation, large opening design, easy and convenient work. The teeth are very strong and have high wear resistance; the steel bar cutter is equipped with high-strength blades.

So the pulverizer can do two jobs at the same time – smashing the concrete and cutting the exposed steel bar, making the crushing operation more efficient.

How Do Hydraulic Pulverizers Improve Work Efficiency?

Driven by hydraulic cylinder, hydraulic pulverize achieves the purpose of crushing objects by controlling the angle between the movable jaw and the fixed jaw.

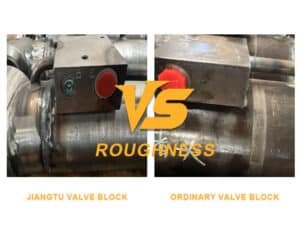

Jiangtu hydraulic pulverizer uses the speed-increasing valve to hydraulically return the oil in the rod cavity of the oil cylinder to the rodless cavity and then increase the speed when the hydraulic cylinder extends outwards, reduce time spent on empty stroke. While keeping the thrust of the oil cylinder unchanged, the operating speed of the oil cylinder is increased and then the working efficiency of hydraulic pulverizer is improved.

The oil cylinder is designed to be installed upside down, which avoids bumps and scratches on the piston rod.

What To Pay Attention To When Choosing Hydraulic Pulverizers?

What type of concrete material are you dealing with? If you need to deal with large quantities of heavy demolition materials or steel bars, hydraulic pulverizer can provide extra breaking force to remove the steel bars.

What Size Excavator Do I Have?

A key factor is your excavator weight and hydraulic requirements. You need to choose a pulverizer that fits your excavator or buy an excavator that fits the pulverizer.

Pulverizer and excavator size depend on the type of work you do and the material you need to handle with. The larger the material you need to grab and crush, the larger the size of your hydraulic pulverizer and excavator.

To choose the model of hydraulic pulverizer and excavator, you can also consult Jiangtu engineer.

Does My Excavator Have Pipelines To Install A Pulverizer?

Cylinder-powered concrete pulverizers have stronger breaking force for better handling of thicker concrete.

Advantages of JIANGTU hydraulic Demolition Pulverizers

If you have any questions about the shear, please feel free to contact us.

Contact For Our Expert

Find out which attachment & Excavator works best for you!