Every business that works in construction knows the importance of having a good set of excavator buckets. It is crucial to have bucket jaws that can take on heavy-duty jobs while still handling delicate tasks.

Excavator buckets are essential not just for the professional but for anyone who uses an excavator to carry out projects. Whether in their backyard or on a job site, any worker needs a reliable set of buckets to ensure everything gets done without hassle and at top efficiency.

With so many types of buckets out there, we thought we would compile this article to help you understand a little more about excavator buckets and how to choose the best one for your needs.

What are Excavator Buckets, and Why Should You Use Them?

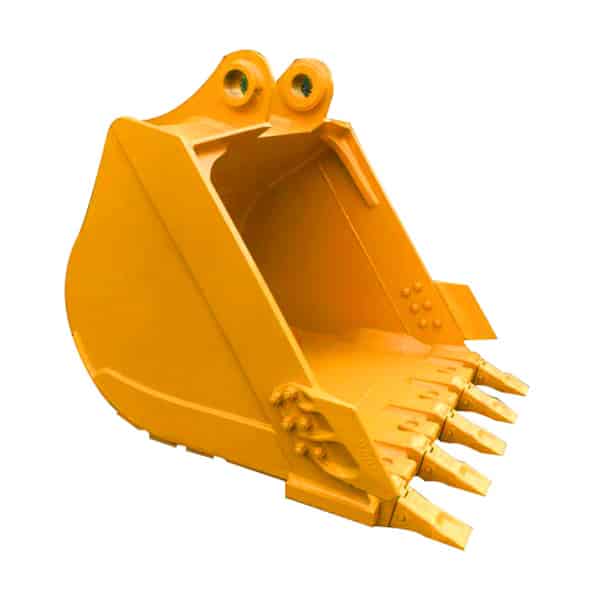

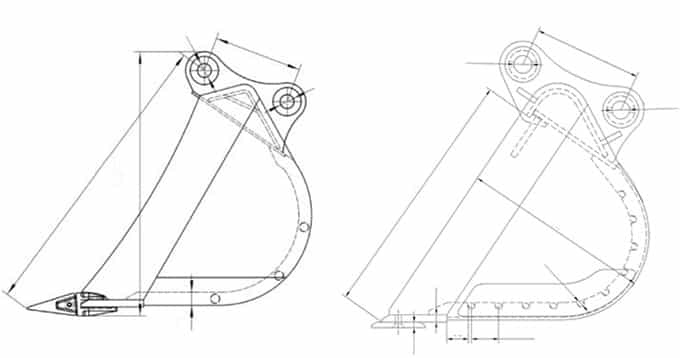

Excavator buckets are designed to be attached to the front of an excavator and used as an extension of its arms. They allow you to dig deeper, lift the bigger weight, and scoop materials out of your way more efficiently than if you were to try by hand alone.

When it comes to working in construction, excavator buckets are essential for getting the job done effectively. They help with digging, loading, and moving large materials and items across a variety of terrains.

What You Need to Know About Your Excavator Buckets

There are a few things that you need to consider when owning and operating an excavator. Here are a few:

What are the different types of buckets available?

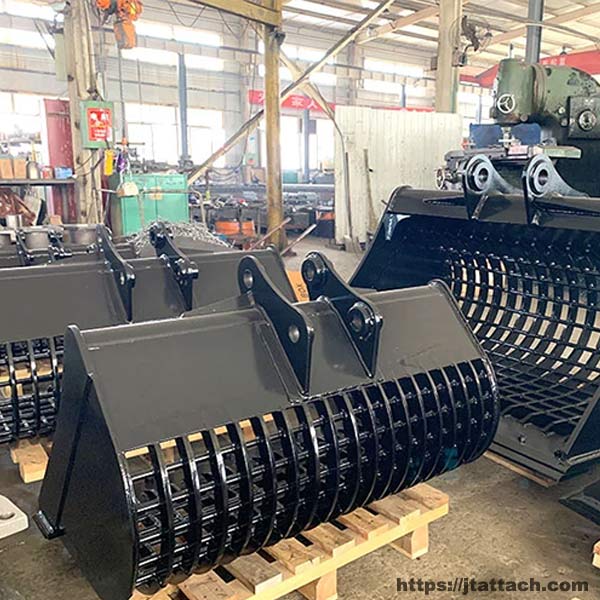

Excavator buckets are available in a variety of styles. Here is a quick overview:

Removable Buckets – This type of bucket comes off and on the machine with ease. These are better suited for jobs where you will need to remove your bucket frequently and adjust its position. The tradeoff to this is that it can be damaged more easily than a fixed-position bucket.

Fixed-Position Buckets – The other option is a solid fixed-position bucket that mounts onto your machine and does not come off. This allows you to work with your bucket, in the same way, every time, which means it will perform better over time while keeping a more consistent grade on the ground.

The most important thing you need to know is that there is no right or wrong option here, just what suits your requirements.

What are the excavator buckets made of?

As with every product category, you’ll find a variety of materials from which excavator buckets are made. In this case, it means steel and aluminum being the main options for bucket construction material.

It is essential to know that aluminum buckets will generally be lighter in weight and easier for your machine to handle, but they also tend to cost more. Steel buckets will be sturdier, better at handling high-pressure loads, and can last longer than aluminum but can take up a little more on the front end of your excavator.

| Product | Materials |

| Skeleton Bucket | Q345B+NM400/NM500, Hardox400/500 |

| Thumb Bucket | Q345B |

| Tilt Bucket | Q460+Q355 |

| Rock Bucket | Q460+Q355 |

How much load can it handle?

As with any product you are purchasing, it is crucial to know the weight that a given product can safely support. This is critical to ensure the safety of yourself and your machine while maximizing performance efficiency.

For example, when choosing an excavator bucket, make sure that you find one that has the right load capacity for what you need to use it for. If you are going to be using it mostly on dirt while carrying lightweight items such as soil and sand, you can get away with a smaller bucket load capacity than if you will be digging through stone and concrete regularly.

| MODEL | JT 02 | JT 03 | JT 04 | JT 06 | JT 08 | JT 10 | JT 14 | JT 20 |

| Weight(kg) | 110 | 260 | 290 | 690 | 1190 | 1780 | 2100 | 2400 |

| Max jaw opening(m/m) | 827 | 1300 | 1400 | 1800 | 2300 | 2500 | 2500 | 2700 |

| Oil pressure(kg/cm2) | 100~130 | 110~140 | 120~160 | 150~170 | 160~180 | 160~180 | 180~200 | 180~200 |

| Set up pressure(kg/cm2) | 150 | 170 | 180 | 190 | 200 | 210 | 220 | 250 |

| Operating flux(lpm) | 15~40 | 30~55 | 50~100 | 90~110 | 100~140 | 130~170 | 180~250 | 250~320 |

| Cylinder volume(ton) | 4 | 5.4 | 5.4 | 8.2 | 10 | 12 | 14 | 15 |

| Apply excavator(ton) | 2~3 | 4~6 | 7~11 | 12~16 | 17~23 | 24~30 | 31~40 | 41~50 |

How often do I need to adjust the angle of my bucket?

Some buckets have a few degrees of movement in the angle that they are held at. This helps you to dig, scoop and move materials quickly. However, if you will be working with your bucket off the ground, it is essential to know how often this level of adjustment can be made while still being considered safe for your machine.

If you need to make frequent angle changes, be sure to choose a bucket that will allow you to do this without harming your machine.

How much will it cost, and how long should it last?

When comparing excavator buckets between brands and types, make sure to factor in the added costs of installation and maintenance into your final decision. This is just as important as the initial price you pay.

While it may cost a little more up front to install, quality will ensure that your bucket lasts longer and works better with your machine for years. If you decide on one that does not get the installation or maintenance requirements that it needs, be prepared to buy another bucket sooner than if you had gone with an option that was built with your machine in mind.

Final Thoughts

Excavator buckets serve a crucial role in the day-to-day operations of any construction, demolition or excavation company. While choosing one may seem like a daunting and confusing task, with the right information, you can make an informed decision that will improve your operations immediately.

As long as you take into consideration the factors discussed in this article, understand that prices will vary depending on your machine and job specifications, and factor in installation costs and maintenance needs, then you are sure to find an excavator bucket that suits your every need.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

![[Major Upgrade]Million-level Spraying Production Line From JAINGTU Heavy Industry Has Officially Started Operation, Achieving New Level of Quality](https://jtexcavator.com/wp-content/uploads/2025/12/06.jpg)