Are you in the construction business and looking for a machine that can help you with your projects? Then a hydraulic plate compactor might be the perfect solution! In this article, we’ll explore what a hydraulic plate compactor is and how it can make your construction projects much easier.

Introduction to Hydraulic Plate Compactor

A hydraulic plate compactor is a construction tool that helps to compress soil and other materials. It uses a large, flat plate to apply pressure to the material, which helps to reduce its volume. This type of compactor is often used on construction projects that involve excavating or backfilling trenches.

Hydraulic plate compactors are available in a variety of sizes and configurations. Some models are designed for use with skid-steer loaders, while others can be mounted on excavators or other types of construction equipment. The size of the machine will determine how much force it can apply to the material being compacted.

Using a hydraulic plate compactor can help to increase the efficiency of your construction project. In many cases, it can help to reduce the amount of time needed to complete the project. Additionally, using this type of compactor can help to improve the quality of the finished product by ensuring that the material is properly compacted.

Jiangtu hydraulic plate compactor is a kind of excavator attachment that is used to compress some types of soil and gravel for construction projects that require a stable subsurface.

JIANGTU hydraulic plate compactor excavator is used for leveling of high-speed way and railway slopes, roads, construction sites, and building floors.

Benefits of Using a Hydraulic Plate Compactor

There are many benefits of using a hydraulic plate compactor for construction projects. One benefit is that it can help to compress the soil, making it dense and less likely to settle or erode over time.

This can be especially helpful when preparing the ground for buildings or other structures. Additionally, using a plate compactor can help to level out uneven surfaces, making them safer and easier to work on.

Compacted soil is also less likely to be disturbed by heavy equipment or foot traffic, making it ideal for foundations and other load-bearing applications. Overall, using a hydraulic plate compactor can save time and money while helping to ensure the long-term success of your construction project.

How to Use a Hydraulic Plate Compactor

If you’re looking for an easy way to compact soil on your construction site, a hydraulic plate compactor is a great option. This type of compactor uses a large, flat plate to compress the soil, making it ideal for use in tight spaces. Here’s how to use a hydraulic plate compactor:

- Position the compactor. Place the hydraulic plate compactor on the ground where you want to compact the soil. Make sure that the plate is flat against the ground and that the machine is level.

- Start the engine. Start the engine of the hydraulic plate compactor and let it warm up for a few minutes.

- Lower the plate. Use the controls on the machine to lower the flat plate onto the ground.

- Move forward. Slowly move the hydraulic plate compactor forward, letting the weight of the machine do most of the work. Don’t apply too much pressure, as this can damage both the machine and the ground.

Different Types of Soils and Gravels That a Hydraulic Plate Compactor Can Compress

There are many different types of soils and gravels that a hydraulic plate compactor can compress. These include sand, clay, loam, and gravel. Each type of soil or gravel has its own unique properties that make it suitable for different construction projects.

Sand is a very fine-grained material that is often used as a foundation for paving projects. It is also sometimes used as an abrasive material for cleaning concrete surfaces. Clay is a type of soil that is made up of very small particles of minerals. It is often used in the construction of adobe buildings and other structures. Loam is a type of soil that contains a mix of sand, clay, and organic matter. It is often used in gardening and landscaping projects. Gravel is a type of rock that is crushed into small pieces. It is often used in the construction of roads and driveways.

Specification – Hydraulic Plate Compactor

The following are the technical parameters of the Hydraulic Plate Compactor.

| Category | Unit | JT-mini | JT-02/04 | JT-06 | JT-08 | JT-10 |

| Height | mm | 435 | 530 | 650 | 720 | 730 |

| Width | mm | 442 | 550 | 700 | 900 | 900 |

| Impulse force | ton | 3 | 4 | 6.5 | 11 | 15 |

| Vibration frequency | rpm/min | 2000 | 2000 | 2000 | 2200 | 2200 |

| Oil flow | l/min | 30-60 | 45-85 | 85-105 | 120-170 | 120-170 |

| Operating pressure | kg/cm² | 100-130 | 100-130 | 100-150 | 150-200 | 150-200 |

| Bottom measurement | mm | 800*442 | 900*550 | 1160*700 | 1300*900 | 1500*1000 |

| Excavator weight | ton | 2-4 | 4-10 | 12-16 | 18-24 | 30-40 |

| Weight | kg | 200 | 350-500 | 650-800 | 900-1000 | 1100-1300 |

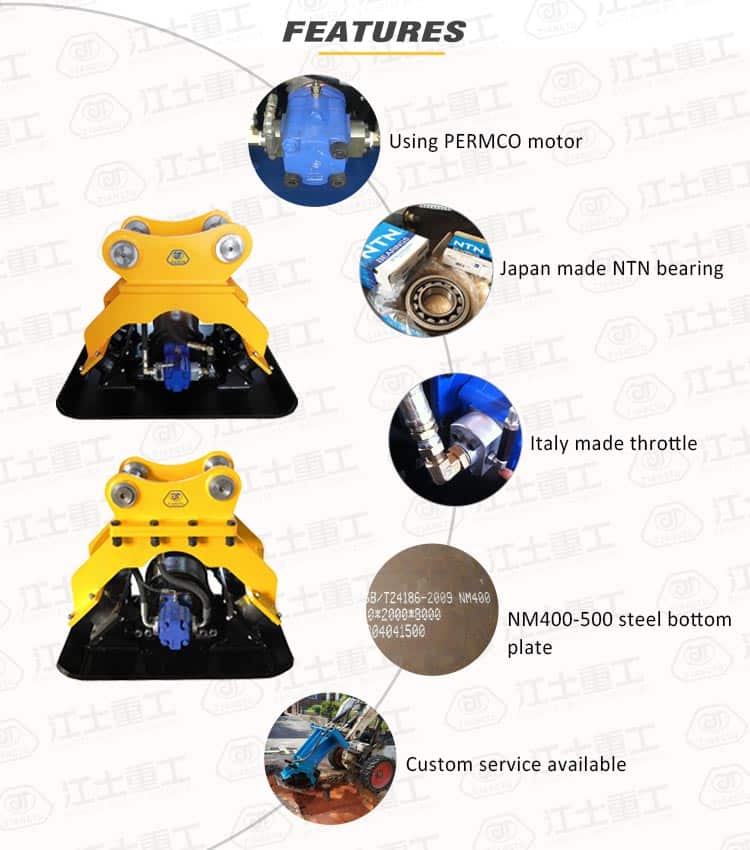

| Mortor Model | Brand PERMCO | 1221081B39 | 1221081B39 | 1215071138 | 1215071048 | M7600-F100NK7676G2 |

| Mortor Displacement | ml/rev | 25.39 | 25.39 | 63.2 | 84.3 | 100 |

Safety Precautions When Operating a Hydraulic Plate Compactor

When operating a hydraulic plate compactor, there are a few safety precautions that should always be followed in order to avoid injury.

Maintenance Tips for Keeping Your Hydraulic Plate Compactor in Optimal Working Condition

If you have a hydraulic plate compactor, it is important to keep it in optimal working condition. Here are some maintenance tips to help you do just that:

- Check the oil level regularly and top up if necessary.

- Keep the compactor clean and free of dirt and debris.

- Inspect the plates regularly for wear and tear, and replace as needed.

- Check all hoses and connections for leaks or damage, and repair or replace as necessary.

- Always use fresh fuel when refilling the compactor’s tank.

By following these simple tips, you can ensure that your hydraulic plate compactor will continue to work efficiently and effectively for many years to come.

Conclusion

A hydraulic plate compactor can be a great choice for those who are looking to make their construction projects easier and faster. By providing excellent compaction performance, the compactor can help ensure that your project is finished on time and within budget. Additionally, its versatility makes it a great tool for any job site, from small residential projects to large-scale commercial developments. With all of these benefits in mind, it’s easy to see why a hydraulic plate compactor is such an essential part of any successful construction project.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

![[Major Upgrade]Million-level Spraying Production Line From JAINGTU Heavy Industry Has Officially Started Operation, Achieving New Level of Quality](https://jtexcavator.com/wp-content/uploads/2025/12/06-300x225.jpg)