Excavator Rotating Grapples in the Forestry Context

Forestry work involves various tasks such as tree removal, logging, debris clearing, land reclamation, and material handling. To perform these tasks efficiently, you need the right tools, and excavator rotating grapples are one of them. These grapples are attachments that can be installed on excavators to facilitate material handling and sorting tasks.

Importance of Suitable Attachments for Forestry Tasks

Choosing the right attachment for your excavator is crucial to ensure efficient and safe work. Forestry tasks require attachments that are specifically designed to handle the unique challenges of the environment, such as rough terrain, heavy loads, and dense vegetation.

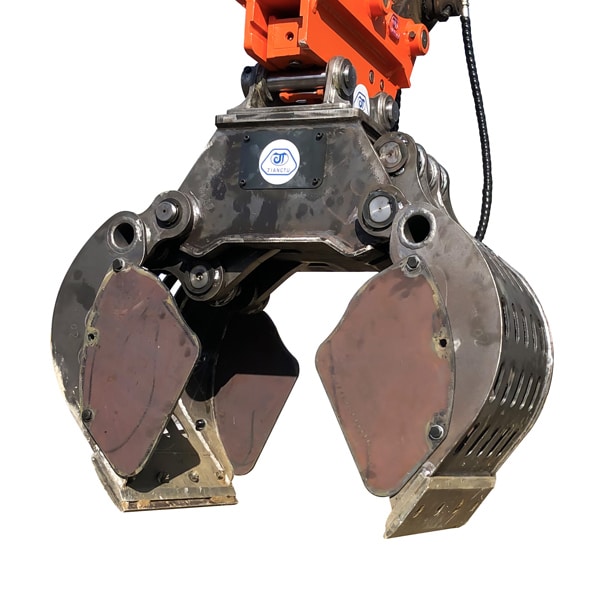

JIANGTU Excavator Grapple is a kind of excavator attachment that is mainly used for steel scraps, wastes handling, loading, and unloading. As one of the leading excavator grapple manufacturers in China, JIANGTU has a full range of hydraulic grapples for excavators from 3-40 tons. They are suitable for all kinds of brands and models of excavators.

Types of Excavator Rotating Grapples

There are two main types of excavator rotating grapples: hydraulic and mechanical grapples. Hydraulic grapples use hydraulic pressure to open and close the jaws, while mechanical grapples rely on the excavator’s movement to operate.

Hydraulic Grapples

Hydraulic grapples are suitable for forestry work because they can handle heavy loads and have a higher degree of control over the gripping force. They come in different sizes and configurations, including single-tine, dual-tine, and four-tine grapples.

Mechanical Grapples

Mechanical grapples are less expensive than hydraulic grapples, but they require the operator to use the excavator’s movement to operate the jaws. They are suitable for light-duty tasks such as debris and brush clearing.

Grapple Options for Forestry Work

Some grapples are specifically designed for forestry work, such as log grapples, root grapples, and brush grapples. Log grapples have longer tines to handle logs, while root grapples have shorter tines and a wider opening to grab tree stumps and roots. Brush grapples have shorter tines and a narrower opening to handle smaller debris.

Further Reading: What are the Differences Between Hydraulic and Mechanical Excavator Grapples?

Primary Applications in Forestry

Excavator rotating grapples have several primary applications in forestry work.

Tree Removal and Logging: Excavator rotating grapples can be used to remove trees by grabbing the trunk or branches and pulling them out. They can also be used to load the logs onto trucks for transportation.

Debris and Brush Clearing: Excavator rotating grapples can be used to clear debris and brush by grabbing and removing them from the site. They can also be used to pile debris for disposal.

Land Reclamation: Excavator rotating grapples can be used to remove invasive plants, such as bushes and small trees, to reclaim land for other uses.

Material Handling and Sorting: Excavator rotating grapples can be used to handle and sort materials, such as rocks and soil, during excavation and construction projects.

Factors to Consider When Choosing a Grapple for Forestry

Choosing the right grapple for your forestry work requires considering several factors.

Excavator Compatibility: Ensure that the grapple you choose is compatible with your excavator’s make and model.

Grapple Size and Capacity: The grapple size and capacity should match the size and weight of the materials you need to handle. Choosing a grapple that is too small for the job can result in slower work and potential damage to the grapple and excavator.

| Wood/Log Grapple | Light Wood Grapple | Orange Peel Grapple | Demolition Grapple | Hydraulic Grab | Hydraulic Grapple | |

| Tine Number | 3+2/3+4 | 1+1 | 4Tine /5Tine | 1+1 | 3+2 | 3+2/3+4 |

| Materials | Q355B and wear plate with M+S motor USA-made solenoid valve Germany-made oil seals | Q355B and wear plate/M+S motor with brake valve; cylinder with USA safety | Imported M+S motor ; NM500 steel and all pins are heat-treated; Original German oil seals; | Q355B and wear plate imported M+S motor; Original German oil seals; | Q355B and wear plate with USA-made solenoid valve; Original Germany-made oil seals and joints | Q355B and wear plate with USA-made solenoid valve; Original Germany-made oil seals and joints |

| Excavator tons | 5-40 ton | 1.5-23 ton | 4-30 ton | 1.5-23 ton | 1.5-30ton | 1.5-30 ton |

| Hot sale area | Global | Global | Global | Europe | Australia | Asia |

Working Environment and Terrain: Consider the type of terrain and working environment you will be operating in. If you are working on steep terrain, you may need a grapple with a larger opening to ensure a secure grip. If you are working in wet conditions, a grapple with a higher degree of control over the gripping force may be necessary.

Maintenance Requirements: Regular maintenance of your grapple is essential to ensure safe and efficient operation. Consider the maintenance requirements of the grapple, including cleaning, lubrication, and regular inspections.

Safety Tips for Using Rotating Grapples in Forestry

Using an excavator rotating grapple in forestry work requires proper training and caution to ensure safety.

Operator Training and Skill: Operators should be trained and skilled in using the grapple attachment and familiar with the manufacturer’s guidelines for safe operation. Proper training and supervision can prevent accidents and ensure efficient work.

Grapple Maintenance and Inspection: Regular maintenance and inspection of the grapple can prevent mechanical failures and ensure safe operation. Operators should inspect the grapple before each use, check for any damage or wear, and perform regular maintenance as recommended by the manufacturer.

Proper Attachment and Operation: Operators should ensure that the grapple is attached properly to the excavator and that the grapple’s weight capacity is not exceedeThey should also operate the grapple with caution, avoiding sudden movements that can cause materials to shift or fall.

FAQs

Conclusion

Excavator rotating grapples are versatile and efficient tools that can enhance your forestry work. Choosing the right grapple for your needs requires considering factors such as excavator compatibility, grapple size and capacity, working environment and terrain, and maintenance requirements. Operators should also follow safety guidelines, including proper training, maintenance, and cautious operation.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

![[Major Upgrade]Million-level Spraying Production Line From JAINGTU Heavy Industry Has Officially Started Operation, Achieving New Level of Quality](https://jtexcavator.com/wp-content/uploads/2025/12/06-300x225.jpg)