JIANGTU new product – the 360° Hydraulic Rotating Pulverizer is on the market along with the cool wind of the Autumn of 2023.

Hydraulic pulverizer, also known as a hydraulic crusher, is a kind of front-end excavator attachment. They can break concrete blocks, columns, etc. and cut and collect the steel bars inside. They are widely used in the demolition of factory beams, houses and other buildings, rebar recycling, concrete crushing, etc.

Hydraulic Rotating Pulverizer

At present, Jiangtu first-generation hydraulic pulverizer is designed as fixed head, which features large crushing force, fast speed and high efficiency, and are more suitable for secondary demolition.

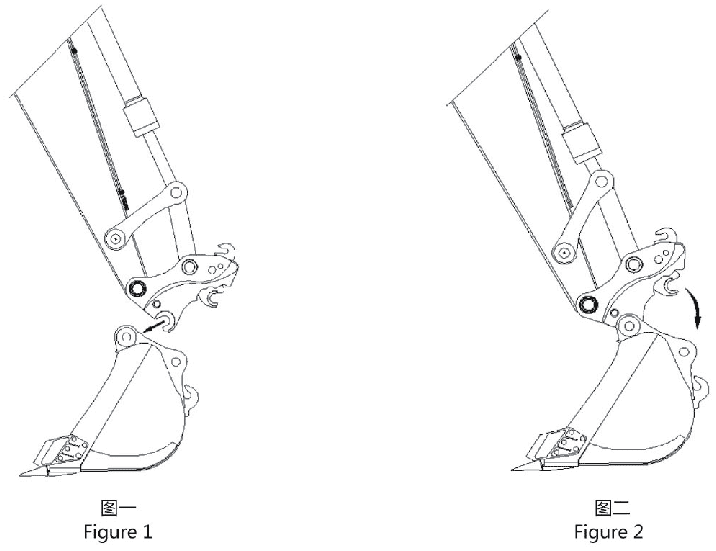

In order to meet the demand of the first demolition, Jiangtu R & D team added a 360-degree rotation function on the pulverizer to improve the maneuverability and precision of accurate operation, and is suitable for the first demolition of floors with different angles and directions.

In addition, considering that the teeth on the pulverizer are quick-wear part, the R & D team designed replaceable teeth for the convenience of replacement, which can be replaced individually or all, so as to reduce the customer’s maintenance cost.

Features of Jiangtu 360°Hydraulic Rotating Pulverizer

Improve the maneuverability and accuracy of the operation

Meanwhile, Jiangtu hydraulic Rotating Pulverizer still retain the characteristics and advantages of ordinary hydraulic pulverizer.

Hydraulic Rotating Pulverizer is widely used in the demolition of factory buildings, beams and columns, civil houses and other buildings, steel bar recovery, concrete crushing, etc., due to its features of no vibration, low dust, low noise, high efficiency and low crushing cost.

Its working efficiency is two to three times that of hydraulic breaker. If needed, let’s talk. Tel/whatsapp: +86-15653818637

Contact For Our Expert

Find out which attachment & Excavator works best for you!