Excavator Quick Coupler are essential components in fluid power systems, designed to facilitate fast and secure connections between hoses, tubes, and various hydraulic components. These connectors enable quick and easy coupling and uncoupling without the need for tools, minimizing downtime and enhancing overall system efficiency.

Importance of Excavator Quick Coupler in Fluid Power Systems

Excavator Quick Coupler play a crucial role in fluid power systems by providing a leak-free connection and ensuring optimal fluid flow. They contribute to system safety, reduced maintenance time, and improved productivity by allowing for swift component changes and preventing spills and contamination.

Overview of the Different Types of Excavator Quick Coupler

Several types of Excavator Quick Coupler exist, each with unique features, applications, and advantages. This article explores the following types:

- ISO A Series Quick Connects

- ISO B Series Quick Connects

- Flat Face Quick Connects

- Screw-to-Connect Quick Connects

- Multi-Coupling Quick Connects

ISO A Series Quick Connects

ISO A Series quick connects, also known as ISO 7241-A, are poppet-style connectors that meet the International Organization for Standardization (ISO) specifications. They feature a ball locking mechanism, ensuring a secure connection, and are available in various sizes and materials, such as steel, brass, and stainless steel.

ISO A Series quick connects are versatile and widely used in several industries, including:

- Agriculture

- Construction

- Manufacturing

- Mobile equipment

Advantages:

- Compliant with ISO standards

- Reliable and secure connection

- Wide range of sizes and materials

Limitations:

- Potential for fluid loss during disconnection

- Not ideal for high-pressure applications

ISO B Series Quick Connects

ISO B Series quick connects, also known as ISO 7241-B, are another type of poppet-style connector conforming to ISO specifications. These connectors use a ball locking mechanism and offer a variety of sizes and materials, similar to the ISO A Series. However, they have a higher pressure rating, making them suitable for more demanding applications.

ISO B Series quick connects are commonly found in industries such as:

- Chemical processing

- Oil and gas

- Pulp and paper

- General industrial applications

Advantages:

- Compliant with ISO standards

- Suitable for higher-pressure applications

- Wide range of sizes and materials

Limitations:

- Potential for fluid loss during disconnection

- Less resistant to contamination compared to flat face connectors

Flat Face Quick Connects

Flat Face quick connects, known for their flat mating surfaces, provide minimal fluid loss during connection and disconnection. These connectors have a push-to-connect design and utilize an internal locking mechanism for secure connections. They are easy to clean and maintain, reducing the likelihood of contamination.

Flat Face quick connects are ideal for applications where cleanliness and minimal fluid loss are crucial, such as:

- Hydraulic excavators

- Skid steer loaders

- Forestry equipment

- Off-highway vehicles

Advantages:

- Minimal fluid loss during connection and disconnection

- Reduced contamination risk

- Easy to clean and maintain

- Suitable for high-pressure applications

Limitations:

- Higher cost compared to poppet-style connectors

- Larger in size and weight

Screw-to-Connect Quick Connects

Screw-to-Connect quick connects are designed for high-pressure applications, utilizing a threaded coupling mechanism. These connectors provide a secure, leak-free connection by screwing the mating halves together, ensuring a tight seal. They are available in various materials and sizes, making them suitable for a wide range of applications.

Screw-to-Connect quick connects are often used in heavy-duty applications where high-pressure resistance is necessary, such as:

- Offshore drilling

- Tunnel boring machines

- Mining equipment

- Injection molding machines

Advantages:

- Excellent high-pressure resistance

- Secure, leak-free connection

- Wide range of sizes and materials

Limitations:

- Longer connection and disconnection times

- Requires proper alignment for successful coupling

Multi-Coupling Quick Connects

Multi-Coupling quick connects enable simultaneous connection and disconnection of multiple hydraulic lines, streamlining the process and reducing downtime. These connectors are available in both plate-mounted and modular designs and can accommodate various types of quick connects, including ISO A, ISO B, and Flat Face connectors.

Multi-Coupling quick connects are ideal for situations where multiple hydraulic lines need to be connected and disconnected frequently, such as:

- Plastic injection molding

- Mobile equipment changeovers

- Industrial automation

- Test benches and equipment

Advantages:

- Simultaneous connection and disconnection of multiple lines

- Reduced downtime and increased productivity

- Compatibility with various quick connect types

Limitations:

- Higher cost compared to single-line connectors

- More complex installation and maintenance

Comparison of Different Types of Excavator Quick Couplers

Factors to Consider When Selecting a Quick Connect Type

When choosing a hydraulic quick connect, several factors should be considered:

- Pressure rating

- Fluid type and compatibility

- Connection and disconnection frequency

- Required cleanliness levels

- Environmental conditions

Matching Quick Connect Types with Specific Applications

Selecting the appropriate quick connect type for a specific application ensures optimal system performance and longevity. To determine the best fit, consider the following recommendations:

- ISO A Series: General-purpose applications with moderate pressure requirements

- ISO B Series: High-pressure applications in various industries

- Flat Face: Applications requiring minimal fluid loss and reduced contamination risk

- Screw-to-Connect: Heavy-duty, high-pressure applications

- Multi-Coupling: Situations requiring frequent connection and disconnection of multiple hydraulic lines

Read More: Excavator Attachments Select Guide

Conclusion

This article has explored the various types of Excavator Quick Coupler, including ISO A Series, ISO B Series, Flat Face, Screw-to-Connect, and Multi-Coupling connectors. Each type offers unique features, applications, and advantages to suit a wide range of fluid power systems.

Choosing the right hydraulic quick connect is crucial for maximizing system performance, safety, and efficiency. By carefully considering factors such as pressure rating, fluid compatibility, and application requirements, users can select the most suitable quick connect type for their specific needs.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

Yantai Jiangtu Showcases Quick Couplers and Grapples at CONEXPO CON/AGG 2026 | Booth C33096

Yantai Jiangtu will present its advanced excavator quick couplers and grapples at CONEXPO CON/AGG 2026, taking place March 3–7 at the Las Vegas Convention Center. As a leading excavator attachment…

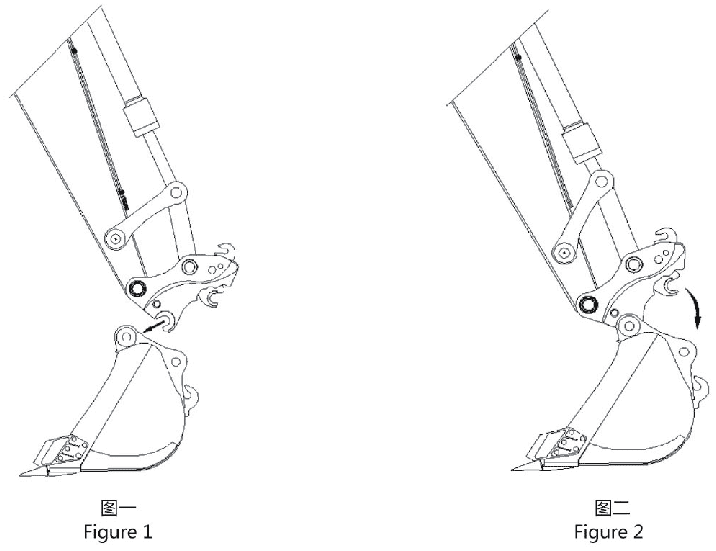

Customer Satisfaction is Our Driving Force – The Story Behind the Hot-selling Tilt Quick Coupler From Yantai Jiangtu

Real feedback from our customer Recently, we received good news from overseas customers.“Yes, one unit sold, customer very happy, also I checked at his place, and no marks about using,…

Empowering Efficiency! JAINGTU Attachments Shine At The Lingong Customer Festival

Attend the event and witness the glory Recently, Lingong Customer Festival site is crowded, Yantai Jiangtu exhibition area is even more hot – a variety of perfectly matched with the…

Customers Praise Jiangtu Quick Coupler – The Rolls-Royce of Quick Coupler

In 2018, a customer purchased one set quick coupler from Yantai Jiangtu,suitable for his Doosan 210 excavator. After years of use, the customer gave it high praise ‘ I’ve been…

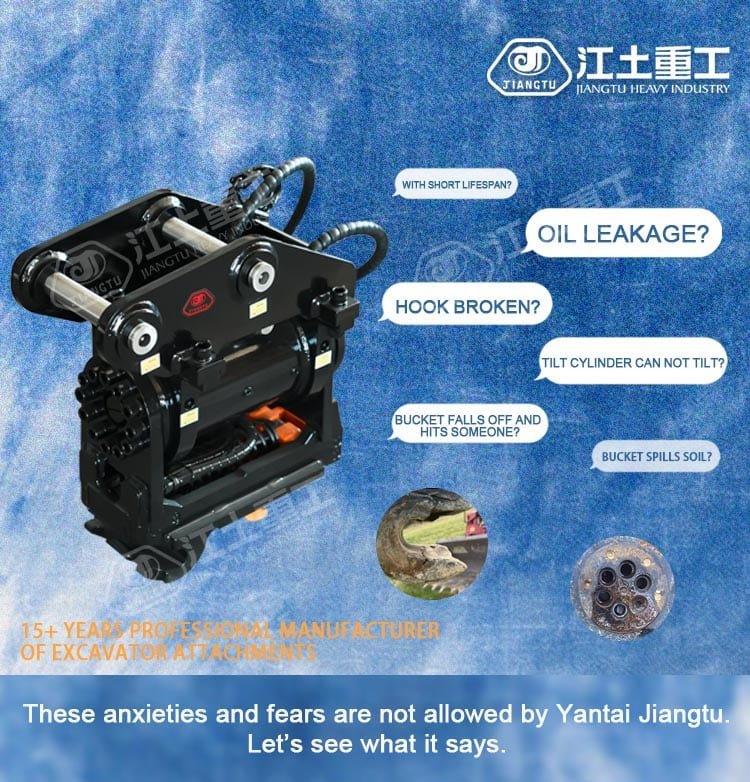

These Problems Are Not Allowed To Occur At All In Jiangtu Quick Coupler

Some Quick Coupler Trouble These anxieties and fears are not allowed by Yantai Jiangtu. Let’s see what it says. Yantai Jiangtu Mechanical Equipment Company is a leading manufacturer of excavator…

Sany Group and Yantai Jiangtujointly held an engineering machinery and attachments exhibition

On June 30, Sany Group and Yantai Jiangtu Mechanical Equipment Co.,LTD jointly held a grand excavator and attachments exhibition in Kunshan city, showing the latest technological innovations and intelligent solutions in the field of…

Jiangtu 13th Anniversary Factory Celebration Ceremony Global Customer Appreciation Feedback

Since its establishment in 2012, Jiangtu has always been adhering to the core values of ‘quality-oriented, integrity-based, service-oriented’, focusing on the research and development and innovation of excavator quick couplers….

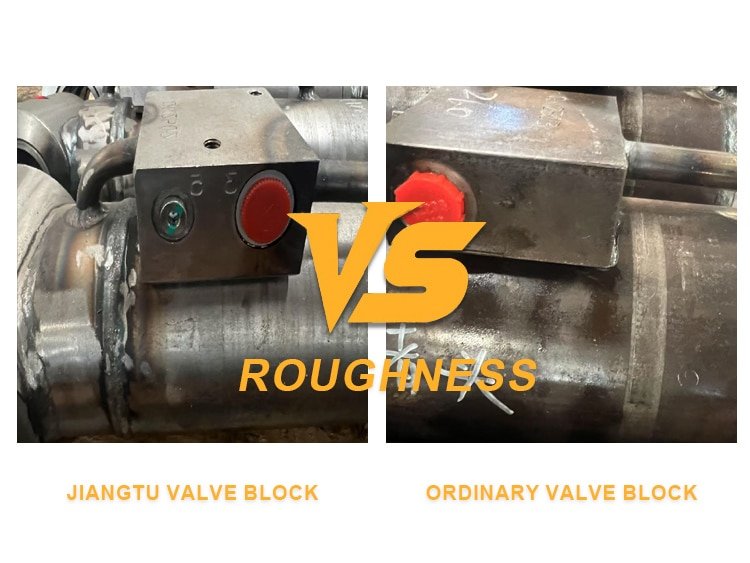

High Quality Cylinder Makes Excellent JIANGTU Quick Hitch Coupler

JIANGTU quick hitch coupler has always been famous for its “good quality and durable use”. Many customers initially chose other brands because of the price, but “the cheaper option” had frequent issues, and then,…