The chisel is wearing part of a hydraulic hammer breaker. The tip of chisel would be worn during the working process, it is mainly used in ore, roadbed, concrete, ship, slag, etc working site. It is necessary to pay attention to the daily maintenance, such as the inner and outer bushes replacement and grease supplement. Otherwise, the chisel would be broken. So the correct selection and use of chisel is the key to hydraulic hammer breaker loss reduction.

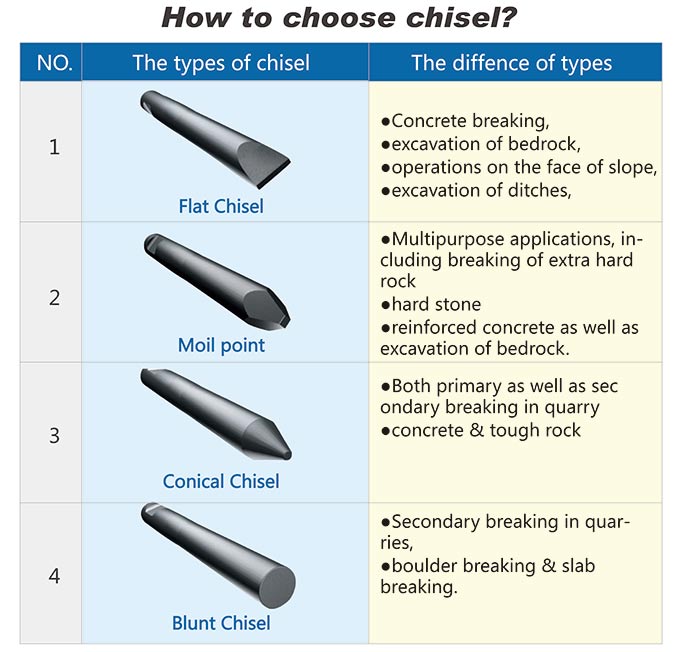

Selection Guide of chisel

- Flat / Wedge chisel: suitable for soft and neutral layer rocks excavation, concrete breaking, and excavation of ditches.

- Moil point chisel: suitable for hard stone, extra hard rock, and reinforced concrete excavation and broken.

- Conical chisel: mainly used in breaking tough rocks, such as granite, and quartzite in quarry, also used for breaking heavy and thickened concrete.

- Blunt chisel: mainly used in breaking medium-hard rocks or small cracked stones to make them smaller

Hydraulic Breaker Chisel

Replacement of chisel

Remove the stop pin and the 330mm long chisel pin at first. When next installing, please insert the chisel into the pin when the chisel is put in the level position.

When re-installing, please proceed in the reverse sequence of disassembly. First, check whether all parts are worn or cracked. It should be polished and repaired If the chisel is deformed. The whole chisel should be coated with lubricate oil, then install the chisel. If the chisel pin is seriously deformed, it is difficult in replacing the chisel. So pay attention to checking the chisel and chisel pin every 100-150 hours.

Operating direction of the chisel

When operating, the direction of the chisel and the excavator’s arm should be the same, and the chisel should be vertical to the rock surface. If the chisel is not vertical to the rock surface, the chisel may slip during work. When breaking, please adjust the chisel direction firstly, and then break the rock from the suitable hitting point of the rock under the stability condition.

Instructions for chisel operation:

- A suitable downward force can improve the efficiency of the hydraulic hammer breaker.

- The position of the hammer breaker adjustment – when the hammer breaker cannot break the rock, it should be moved to a new hitting point.

- The breaking operation shall not be operated continuously at the same position. The the temperature of chisel would rise when breaking at the same position for a long time. The chisel hardness would be reduced to damage the tip of chisel, thereby the operation efficiency cut down.

- Do not use the chisel as a lever to pry rocks.

- Please put down the excavator arm to a safe state when stopping operation. Don’t leave the excavator when the engine is started. Please ensure all brake and locking devices ineffective state.

Read More: Excavator Attachments Select Guide

JIANGTU Attachments, as a breaker manufacturer for 12 years. We could provide various types of hydraulic hammer breakers and the chisel selection recommendation and installation instructions for you. If you have any questions, please feel free to contact us.

JIANGTU Excavator Break adopts special carbon steel material and heat treatment processes to ensure that the wear of the piston hitting surface is minimized and the service life of the piston is maximized.

Piston production adopts precise tolerance control to ensure that the piston and cylinder can be replaced with a single product, reducing maintenance costs.

The shell of the breaker has put forward higher and higher requirements for its sealing system. The NOK brand oil seals ensure our hydraulic breaker has low (zero) leakage, low friction and wear, and long service life.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

![[Major Upgrade]Million-level Spraying Production Line From JAINGTU Heavy Industry Has Officially Started Operation, Achieving New Level of Quality](https://jtexcavator.com/wp-content/uploads/2025/12/06-300x225.jpg)