Excavator hydraulic shears are widely used in steel structure demolition, scrap steel recycling, automobile dismantling and other industries. It is a wise choice to choose the appropriate hydraulic shear according to your own working conditions.

However, there are many types of hydraulic shears, such as olecranon shears, double-cylinder shears, car demolition shears, mechanical olecranon shears, etc.

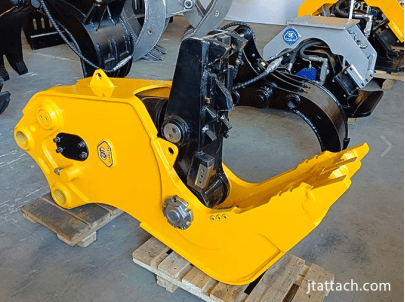

No.1 Double Cylinder Hydraulic Shear

As the name suggests, it is a hydraulic shear with two oil cylinders. It has a wide range of uses, mainly for crushing and demolition of houses, chemical equipment, etc. Generally, high-strength wear-resistant plates are used for the shear, which has high machining accuracy and is not easy to deform.

The two scissor boards have synchronizing devices, which make the shear open and close synchronously and powerfully. The excavator’s hydraulic shear can rotate 360 degrees, improving work efficiency.

No.2 Single Cylinder Pulverizer

In construction sites, single-cylinder hydraulic pulverizers are often used.

It has the following features: static crushing, no vibration, ensuring structural safety; no dust, no noise, small broken pieces are easy to clean and transport; partial demolition, retaining reinforcement; Fast and efficient crushing and low cost, suitable for crushing static demolition projects such as house beams, cement poles, floor slabs, etc., and it is easy to use.

No.3 Steel Shear

Steel shears are also composed of two oil cylinders, which are mainly suitable for cutting steel bars and rigid structures. High-strength wear-resistant plates are used on the shear, which has good wear resistance and high shearing force.

The alloy blades developed for steel shearing are added to improve construction efficiency and meet customers’ needs for recycling metals with strong hardness such as super-hard steel plates and steel bars.

No.4 Olecranon Shear

The olecranon Shear is a heavy-duty hydraulic shear installed on the excavator. Its unique design and innovative method ensure efficient operation and powerful cutting force, which exceeds the performance of ordinary hydraulic shears by 15% and is one of the largest shearing forces among excavator hydraulic shears.

It is suitable for the treatment of sheared steel bars, steel plates, steel materials, tanks, pipes, etc.

It is characterized by easy movement, flexible use on any occasion, high speed, high efficiency, high safety, and more in line with environmental protection requirements.

No.5 Car Dismantling Shears

The excavator car dismantling shear is mainly used for dismantling scrapped cars and cutting car frames.

They can rotate 360 degrees. With the special press frame, it is more convenient for the shear to dismantle large and small scrapped cars and save labor costs. It is an essential machine for car dismantling plants.

Excavator car dismantling shears have high work efficiency, high safety factor, and long-term return on one-time investment. It is a new working tool in the scrap car recycling and dismantling industry.

Read More: Excavator Attachments Select Guide

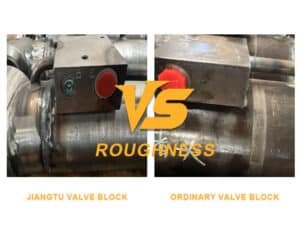

Advantages of JIANGTU hydraulic shears

- The closed steel plate structure eliminates and reduces twisting or bending deformation on any side.

- The special blade design improves productivity and facilitates blade replacement, which can reduce machine downtime and optimize productivity.

- The enlarged hydraulic cylinder greatly strengthens the closing force of the jaws so that the hard steel can be cut.

- The product is made of high-grade steel, with anti-corrosion treatment and a waterproof design, which ensures the strength and wear resistance of the tool.

- The installation of the hydraulic shear is simple. Connect the pinhole to the pinhole at the front end of the excavator, and connect the breaker pipeline on the excavator to the hydraulic shear, which is convenient to use alternately with the breaker.

If you have any questions about the shear, please feel free to contact us.

Contact For Our Expert

Find out which attachment & Excavator works best for you!