Excavation work can be daunting and time-consuming, especially when you don’t have the right tools for the job. One of the most important pieces of equipment in your arsenal is an excavator bucket. But with so many different types available on the market, how do you know which one is best suited for your project?

Whether you’re digging trenches, moving materials or demolishing structures, selecting the right excavator bucket can make all the difference between a successful project and a frustrating waste of time and money. In this blog post, we’ll guide you through everything you need to know to choose the perfect excavator bucket for your next excavation mission!

Understanding Excavator Bucket Types

There are many different types of excavator buckets to choose from, and each one is designed for a specific purpose. When you’re choosing an excavator bucket for your project, it’s important to understand the differences between each type so that you can select the right one for the job.

The most common type of excavator bucket is the general purpose bucket. These buckets are used for a variety of tasks, including digging, loading, and carrying material. General purpose buckets are available in a variety of sizes to accommodate different excavators.

Another common type of excavator bucket is the digging bucket. Digging buckets are designed specifically for digging operations. They typically have a pointed bottom that helps penetrates the soft ground and teeth or cutting edge that helps break through hard ground. Digging buckets are available in a variety of sizes to accommodate different excavators.

A third type of excavator bucket is the specialty bucket. Specialty buckets are designed for specific tasks, such as dredging, grading, or sorting material. Specialty buckets are available in a variety of sizes to accommodate different excavators.

The Ultimate Guide to Excavator Bucket: Types and Their Applications

Evaluating Project Requirements

When it comes to excavator buckets, there are many different types and sizes to choose from. With so many options available, it can be difficult to know which bucket is right for your project. In this article, we will discuss how to evaluate project requirements in order to choose the right excavator bucket for the job.

There are a few factors you will need to consider when evaluating project requirements:

- The type of material you will be digging: There are different types of excavator buckets designed for different materials. For example, if you are digging in soft soil, you will need a bucket with teeth that can penetrate the ground easily. However, if you are digging in hard rock, you will need a bucket with carbide-tipped teeth that can break through the tough surface. Knowing what type of material you will be digging will help you narrow down your choices.

- The depth of the hole: Excavator buckets come in different sizes, so you will need to know how deep your hole needs to be before choosing one. If you have a very deep hole, you will need a large bucket so that it can hold more material. On the other hand, if your hole is not very deep, you can save money by choosing a smaller bucket.

- The width of the hole: Just like with depth, excavator buckets come in different widths as well. You will need to know how wide your hole needs to be before

Excavator Bucket Capacity and Size

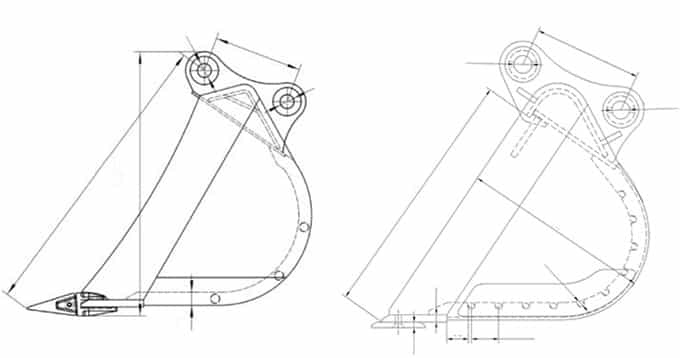

The size and capacity of an excavator bucket are determined by the width of the bucket, length of the bucket, and the volume of the bucket. The width of the bucket is measured in inches, while the length is measured in feet. The volume is measured in cubic yards.

When it comes to choosing an excavator bucket, size and capacity are two important factors to consider. The width of the bucket will determine how much material can be scooped up at one time, while the length will determine how far the excavator can reach. The volume is important for determining how much material can be hauled in a single load.

There are a variety of different sizes and capacities of excavator buckets available on the market today. To choose the right one for your project, it’s important to first assess your needs and then compare different models to find the best match.

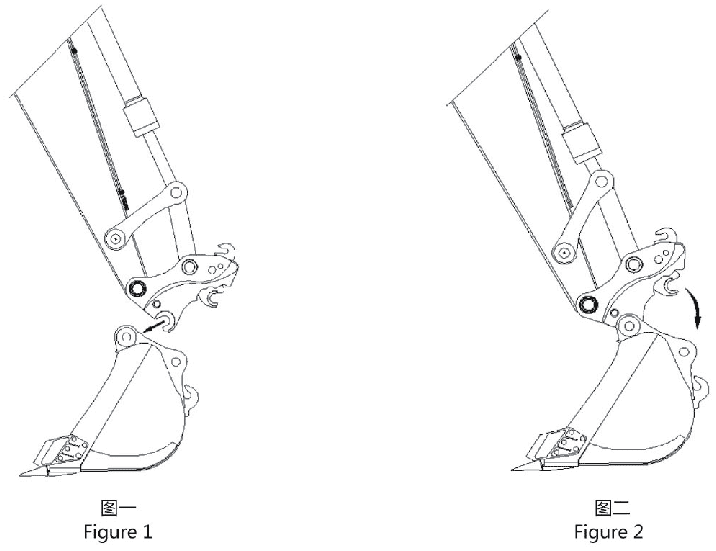

Bucket Attachment System

An excavator bucket attachment system is a key component in ensuring that your equipment can handle the demands of your project. There are a few factors to consider when choosing an excavator bucket attachment system, including:

- The type of excavator you have

- The size and scope of your project

- Your budget

The type of excavator you have will dictate the kind of bucket attachment system you need. For example, if you have a mini excavator, you’ll need a mini excavator bucket attachment system. Similarly, if you have a full-size excavator, you’ll need a full-size excavator bucket attachment system.

The size and scope of your project will also dictate the kind of bucket attachment system you need. If you’re working on a small construction site, for instance, you won’t need an industrial-grade bucket attachment system. Conversely, if you’re working on a large construction site or demolition project, you’ll need an industrial-grade bucket attachment system that can handle the heavy loads.

Finally, your budget will play a role in choosing an excavator bucket attachment system. If you have a limited budget, there are still quality options available; it just may take some time to find the right one for your needs.

Read More: Excavator Attachments Select Guide

Material and Build Quality

Choosing the right excavator bucket for your project is important for two reasons: material and build quality. The material of your bucket will determine its durability and performance, while the build quality will affect its overall lifespan.

When it comes to materials, there are three main options: steel, aluminum, and composite. Steel is the most common choice for excavator buckets because it is strong and durable. However, it is also the heaviest option, which can impact fuel efficiency. Aluminum is a lighter alternative to steel that offers good strength and durability. Composite buckets are made from a combination of materials, including steel, aluminum, and synthetic polymers. They are often lighter than steel buckets and can offer better wear resistance.

When it comes to build quality, there are a few things to consider. First, check the welds to ensure they are strong and well-done. Second, look at the teeth or cutting edge of the bucket – these should be made from high-quality materials that are designed to withstand heavy use. Finally, examine the overall construction of the bucket to ensure that it is built tough and will last for years to come.

Excavator Bucket Maintenance

Most excavator buckets will require some level of maintenance in order to keep them functioning properly. Here are a few tips on how to maintain your excavator bucket:

- Inspect your bucket regularly for any signs of wear or damage.

- If you notice any damage, repair or replace the affected parts as soon as possible.

- Keep the bucket clean and free of debris to prevent damage to the working components.

- Lubricate the moving parts on the bucket regularly to ensure smooth operation.

Environmental and Regulatory Considerations

There are a variety of environmental and regulatory considerations to take into account when choosing an excavator bucket for your project. First and foremost, you will need to consider the local regulations in your area regarding the use of excavators. In some cases, you may need to obtain a permit from your local municipality in order to use an excavator on your project site.

Additionally, you will need to take into account any environmental sensitivities in the area, such as wetlands or endangered species habitat. If you are working in an environmentally sensitive area, you may need to use a specially designed bucket that minimizes the impact on the surrounding ecosystem. Finally, you will also need to consider the long-term effects of your choice of excavator bucket. For example, if you are working in an area with groundwater contamination, you will want to choose a bucket that is made from materials that will not leach chemicals into the water supply.

Analyzing Return on Investment (ROI)

The first step in any equipment purchase is understanding your needs and what you hope to achieve with the new addition. For excavators, this process begins with a thorough analysis of the return on investment (ROI) that the machine will bring to your project. Here are a few key considerations to keep in mind when evaluating ROI for an excavator bucket:

1. What is the expected lifespan of the bucket?

2. How often will the bucket be used?

3. What is the cost of ownership (including maintenance and repairs)?

4. How much material can be processed per hour/day/week?

5. How does the bucket compare to other options on the market?

By taking all of these factors into account, you can get a clear picture of whether or not an excavator bucket is a good investment for your project. If you have any doubts, be sure to consult with an experienced excavator operator or dealer before making your final decision.

Conclusion

With a little bit of research and understanding, you can choose the right excavator bucket for your project. These buckets come in many shapes and sizes, each designed for different jobs or environments. You should always consult with an expert before selecting the best bucket to make sure it fits your needs perfectly. Taking these steps will ensure that you have the right tool for the job and get the results that you need from your excavation project.

JIANGTU Excavator Bucket is the perfect choice for grading and leveling earthwork. Obliquely manipulate this excavator attachment to the precise angle required, so that you are more efficient in handling work, and do not have to constantly reposition your excavator.

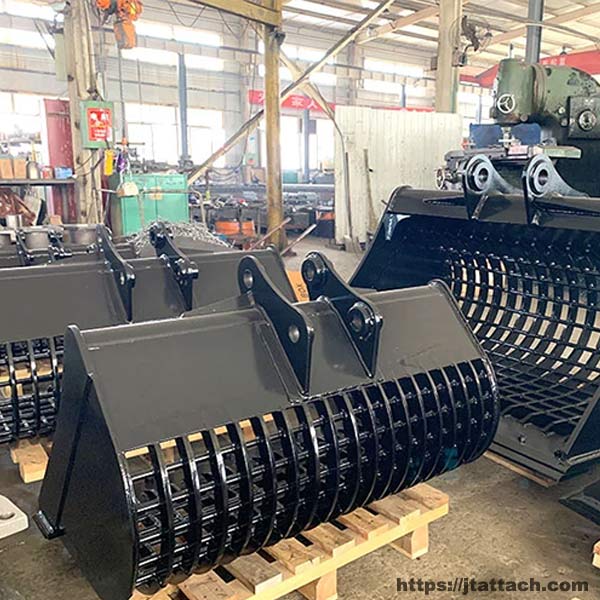

As one of the leading Excavator Buckets manufacturers in China, JIANGTU has a full range of excavator buckets for machines from 1.5-25 tones. Included in the range is thumb bucket, tilt bucket, skeleton bucket, clean up bucket, grab bucket, rock bucket, ripper bucket, mini-excavator buckets.

Contact For Our Expert

Find out which attachment & Excavator works best for you!