Unleash the power of your excavator with an incredible piece of machinery: the excavator breaker chisel! If you’ve ever marveled at how effortlessly these heavy-duty machines tear through concrete, rock, and other tough materials, then you have witnessed the sheer force and precision of a breaker chisel in action.

In this blog post, we will dive deep into the world of hydraulic breakers and explore everything you need to know about excavator breaker chisels. From their components and working principles to their applications and maintenance tips – get ready to unearth all the secrets behind these mighty tools. So grab your hard hat and let’s dig right in!

Components of an excavator breaker chisel

Excavator breaker chisels are powerful tools that are used in various industries for demolition and construction purposes. They consist of several key components that work together to deliver high-performance results.

One of the main components is the steel body, which provides strength and durability to withstand heavy-duty operations. The body is designed to handle extreme forces and vibrations without compromising its integrity.

The working end of the excavator breaker chisel is fitted with a hardened steel tip, also known as the tool bit or moil point. This tip is responsible for delivering impact force to break through tough materials such as concrete, rock, or asphalt.

To ensure efficient operation, hydraulic fluid flows through the internal chambers within the chisel. These chambers act as a power source for generating energy and transmitting it to the tool bit. The hydraulic system allows for precise control over impact force and ensures smooth operation.

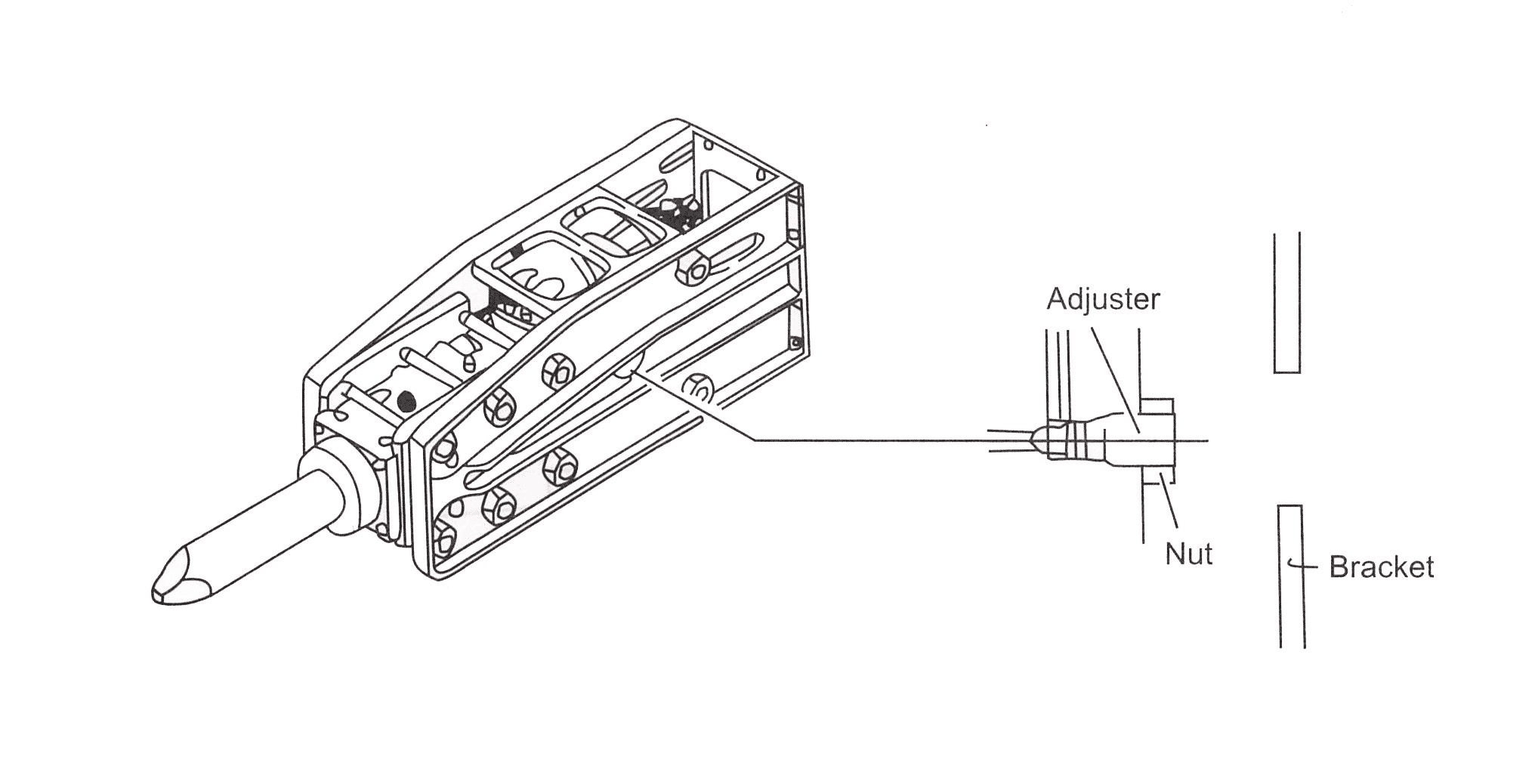

Another important component is the mounting bracket, which attaches the excavator breaker chisel to the arm or boom of an excavator. It provides stability during operation and allows for easy attachment/detachment when required.

In addition to these main components, there may be additional features like shock absorbers or dampening systems built into some models. This help reduces vibration transfer back to the operator’s cab, improving comfort and reducing fatigue during prolonged use.

Each component plays a crucial role in enhancing performance and productivity while using an excavator breaker chisel. With proper maintenance and care, these components can provide reliable service on various job sites across different industries.

Specification – Hydraulic Breaker Chisel

| Model | Size | Material |

| SB20 | Φ45*500 | 40Cr or 42CrMo |

| SB30 | Φ53*580 | 40Cr or 42CrMo |

| SB40 | Φ68*700 | 40Cr or 42CrMo |

| GB2T | Φ70*700 | 40Cr or 42CrMo |

| SB43 | Φ75*750 | 40Cr or 42CrMo |

| SB45 | Φ85*850 | 40Cr or 42CrMo |

| SB50 | Φ100*1000 | 40Cr or 42CrMo |

| SB81N/GB8AT | Φ135*1300 | 40Cr or 42CrMo |

| SB81 | Φ140*1300 | 40Cr or 42CrMo |

| SB100 | Φ150*1500 | 40Cr or 42CrMo |

| SB121 | Φ155*1500 | 40Cr or 42CrMo |

| SB131 | Φ165*1600 | 40Cr or 42CrMo |

| SB151 | Φ175*1700 | 40Cr or 42CrMo |

Working principle of an excavator breaker chisel

The working principle of an excavator breaker chisel is quite fascinating. These powerful tools are designed to break through tough materials like concrete and rock, making them essential in various construction and demolition projects.

When the hydraulic breaker is attached to the excavator, it utilizes the machine’s hydraulic system to deliver high-pressure oil flow to the chisel. The oil flow creates intense pressure within the breaker, which is then released through a valve when triggered by the operator.

As this pressurized oil flows into the piston chamber of the breaker, it pushes against a piston head connected to a steel chisel. The force generated causes rapid reciprocating motion of the chisel at high speeds, striking against the material with immense impact.

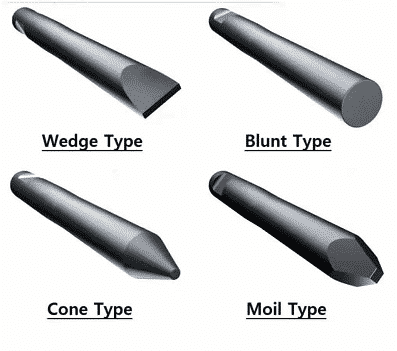

The repeated blows from the chisel effectively fracture and disintegrate even stubborn surfaces, allowing for efficient excavation or removal. It’s important to note that different types of chisels can be used depending on specific requirements – such as moil point chisels for breaking rocks or flat wedge-shaped ones for demolishing concrete structures.

Understanding how an excavator breaker chisel works highlights their incredible power and effectiveness in tackling demanding tasks on construction sites. Whether it’s breaking up old pavement or demolishing walls, these tools play a crucial role in getting things done efficiently and quickly!

Applications of excavator breaker chisels

Excavator breaker chisels, also known as hydraulic breakers or rock breakers, have a wide range of applications in various industries. These powerful tools are designed to break through hard materials such as concrete, asphalt, and rocks with ease. Let’s take a look at some of the common applications where excavator breaker chisels prove invaluable.

The versatile nature of excavator breaker chisel makes them indispensable across multiple industries. They provide efficiency, safety, and cost-effectiveness in various applications ranging from construction and mining to quarrying and road maintenance.

Selection and maintenance of excavator breaker chisels

Selection and maintenance are crucial aspects when it comes to excavator breaker chisels. Choosing the right chisel for your excavator is essential to ensure optimal performance and productivity. Consider factors such as the type of material you will be breaking, the size and weight of your excavator, and the specific requirements of your job site.

When selecting a breaker chisel, make sure it is compatible with your excavator’s hydraulic system. The size, shape, and mounting configuration should match perfectly to avoid any compatibility issues. Additionally, consider the durability and strength of the chisel material to withstand tough working conditions.

Regular maintenance is vital to prolonging the lifespan of your breaker chisels. Inspect them before each use for signs of wear or damage. Check for cracks or fractures in the tool steel as these can compromise its effectiveness and safety during operation.

Proper lubrication is also essential for smooth functioning of the chisel. Use recommended grease or oil specified by the manufacturer on a regular basis.

Additionally, keep an eye on hydraulic pressure levels to ensure they remain within the correct range. Excessive pressure can lead to premature wear while insufficient pressure may result in poor performance.

Safety considerations when using excavator breaker chisels

When it comes to operating heavy machinery like excavators, safety should always be the top priority. This is especially true when using excavator breaker chisels, as they can be powerful tools that require careful handling. Here are some important safety considerations to keep in mind:

Remember that these are just some general safety considerations when using an excavator breaker chisel; always refer to specific guidelines provided by your employer or equipment manufacturer for comprehensive instructions tailored to your specific situation.

Conclusion

Excavator breaker chisels are essential tools in the construction and demolition industry. With their powerful hydraulic systems and durable chisel heads, they can effectively break through tough materials like concrete and rock. These versatile attachments have revolutionized the excavation process by increasing efficiency and reducing labor-intensive methods.

When selecting an excavator breaker chisel, it is crucial to consider factors such as compatibility with your machine’s specifications, the type of work you will be doing, and the material you need to break. Regular maintenance is also key to ensuring optimal performance and longevity of your equipment.

However, it’s important to always prioritize safety when using excavator breaker chisels. Proper training on operating procedures and adherence to safety guidelines can prevent accidents or injuries on-site.

So whether you’re involved in heavy construction projects or smaller-scale demolition jobs, investing in a reliable excavator breaker chisel can greatly enhance your productivity while minimizing manual labor requirements.

Remember that choosing the right tool for the job is essential for getting the best results. So make sure to do thorough research before purchasing an excavator breaker chisel that suits your specific needs.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

What Is Excavator Breaker Chisel?

Unleash the power of your excavator with an incredible piece of machinery: the excavator breaker chisel! If you’ve ever marveled at how effortlessly these heavy-duty machines tear through concrete, rock,…

Installation Guide and Instructions for Excavator Quick Hitch

How to install the pipeline of excavator quick hitch and attention points during the processing are shared as below. It is simple. If you are interested, welcome to check. Installation…

Hydraulic Breakers Trouble Shooting and Solution

This trouble-shooting guide has been prepared to aid the operator to locate the problem cause and then remedy when trouble has occurred. If trouble has been caused, obtain details as…

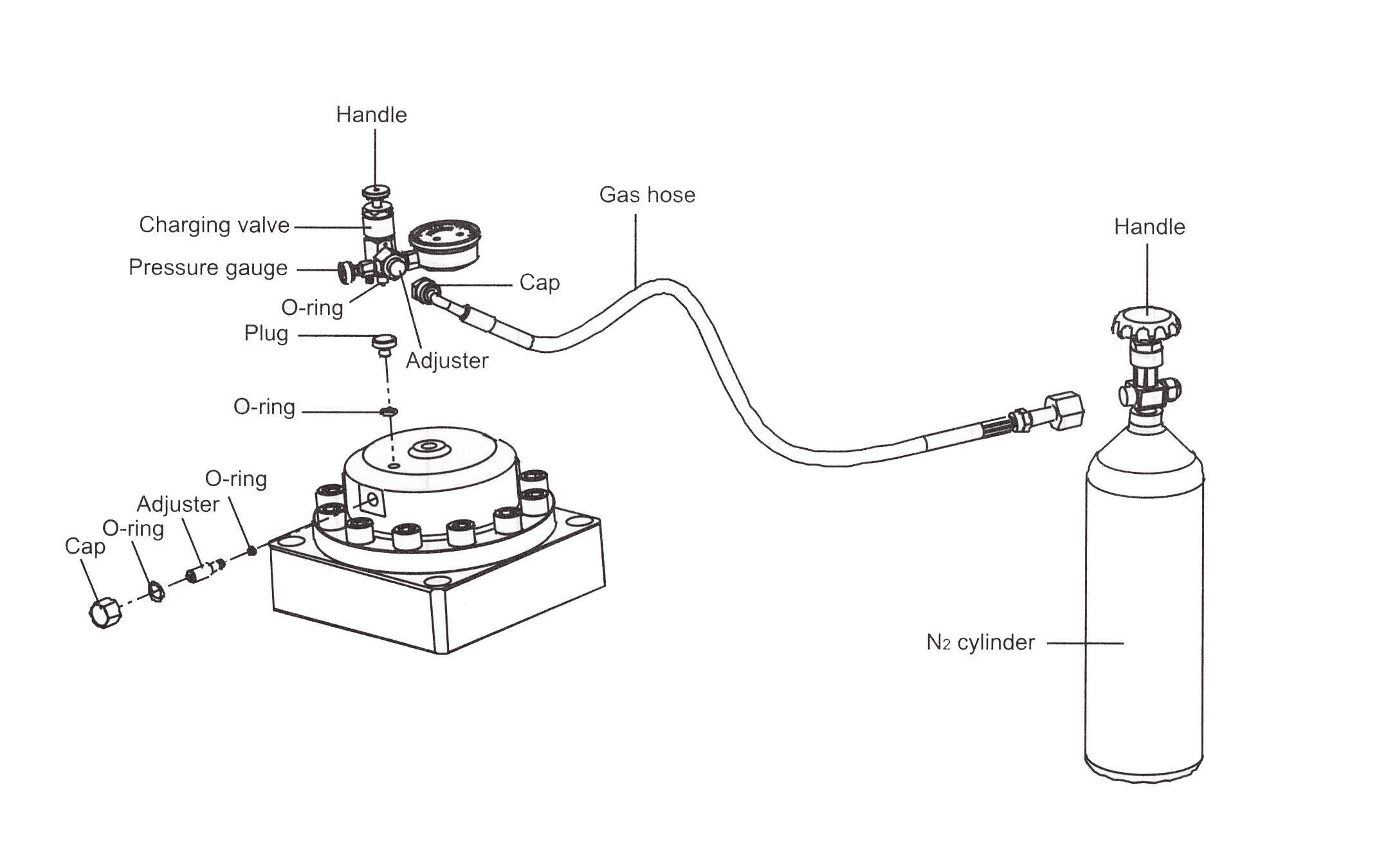

How to Adjust Hydraulic Breaker for Mini Excavator

Before starting the base machine which the hydraulic breaker is mounted, check to use the machine safely and to prevent any trouble. Operation includes the following: Cylinder Adjuster The hydraulic…

How to Maintain Hydraulic Breaker for Mini Excavator

Excavator hydraulic breakers are usually used to break rock, concrete, asphalt and other construction and aggregate materials. However, Wear and tear is an outright certainty, so maintaining the breaker is…

How to Install and Remove Hydraulic Breaker for Mini Excavator

A Hydraulic Breaker, also known as a percussion hammer, is a heavy mechanical device used to demolish concrete, asphalt, or stone materials. Hydraulic breakers are commonly seen in road construction and…

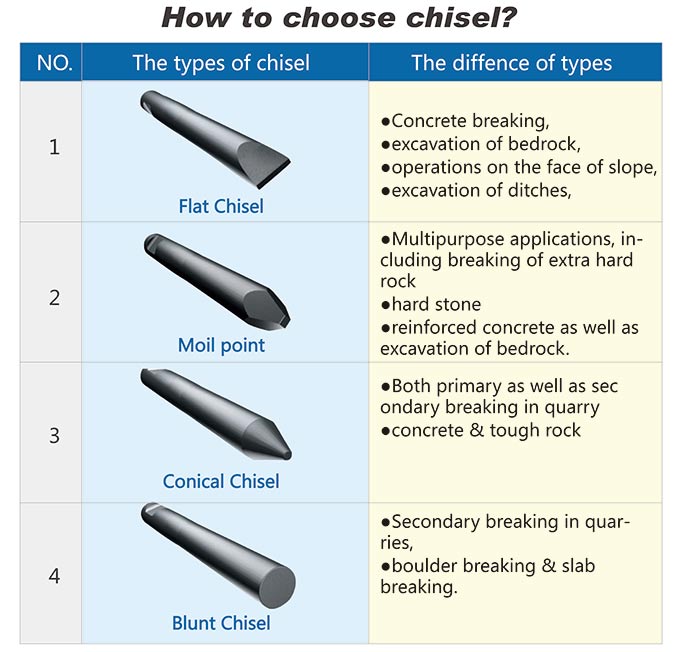

How to Select Breaker Chisel Tools for Hydraulic Hammer

The chisel is wearing part of a hydraulic hammer breaker. The tip of chisel would be worn during the working process, it is mainly used in ore, roadbed, concrete, ship,…

Tips to Maximize Hydraulic Breaker Life

People engaged in the excavator industry must be no stranger to hydraulic breakers. For operators, choosing a hammer rightly, using the hammer correctly, and maintaining the hammer properly are the…