A crusher bucket is a revolutionary attachment designed to transform traditional excavators into powerful mobile crushers. As an innovative solution for on-site crushing and recycling of materials, crusher buckets have become increasingly prevalent in various industries. These versatile attachments offer an efficient and cost-effective way to process inert materials such as concrete, rocks, asphalt, and natural stones directly at the job site.

In this article, we will explore the functionality, benefits, and applications of crusher buckets, shedding light on their importance in modern construction and recycling practices.

Types of Crusher Buckets

Crusher buckets are available in a variety of models, each designed to cater to specific crushing requirements and material types. These attachments can be tailored to suit various excavator sizes and capabilities, making them versatile and adaptable for different projects. The selection of the right crusher bucket depends on factors such as the desired output size, the hardness of the material being crushed, and the specific application.

Some crusher bucket models are specifically optimized for crushing concrete and rocks, providing powerful and efficient performance in demolition and construction projects. These buckets are equipped with robust crushing jaws and sharp teeth to break down tough materials with ease. On the other hand, there are crusher buckets designed for processing inert materials like soil, clay, and pebbles, which are often used in landscaping and land reclamation projects.

Crusher Bucket

How Crusher Buckets Work

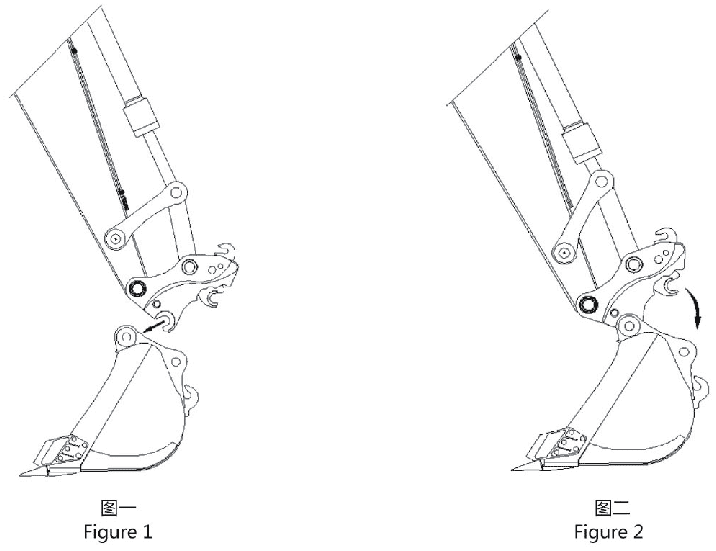

Crusher buckets are innovative attachments that utilize the excavator’s hydraulic system to power the crushing mechanism. The attachment is mounted on the excavator’s boom and operates using its standard hydraulic functions. When in action, the crusher bucket’s powerful jaws compress and crush the material against a fixed jaw, breaking it down into smaller, manageable pieces.

The crushing process is highly efficient, allowing the excavator operator to control the output size of the crushed material. The adjustable jaw gap enables different output sizes to be achieved, making the crusher bucket versatile for various applications. Additionally, some crusher buckets come with interchangeable crushing plates, allowing contractors to adapt the attachment to different materials and job requirements.

The compatibility of crusher buckets with different types of excavators further enhances their usability. These attachments can be easily fitted to a wide range of excavator models, regardless of size or brand, providing contractors with flexibility in their equipment choices. The integration of the crusher bucket with the excavator’s hydraulic system ensures smooth and consistent performance, enabling contractors to process materials efficiently directly at the job site.

Read More: Excavator Attachments Select Guide

Common Applications of Crusher Buckets

Crusher buckets offer versatile functionality for a wide range of applications in various industries. Here are some common applications of crusher buckets:

- Crushing and recycling concrete and rocks:

- Demolition sites

- Construction projects

- Road and infrastructure works

- Handling and processing inert materials:

- Landscaping projects

- Land reclamation

- Site preparation

- Landscaping and land reclamation projects:

- Creating pathways and trails

- Clearing and leveling land

- Reclaiming unused or disturbed areas

- Quarrying and mining operations:

- Extracting and processing minerals

- Crushing and screening aggregates

- Sorting and separating materials

- Environmental remediation:

- Remediation of contaminated soil

- Processing waste materials

- Landfill management and compaction

- Agricultural applications:

- Processing organic materials

- Grinding and crushing agricultural waste

- Composting and soil enhancement

- Forestry and land clearing:

- Clearing vegetation and underbrush

- Processing wood waste

- Creating firebreaks and access roads

Crusher buckets excel in these applications, providing on-site material processing capabilities that streamline operations and reduce the need for additional machinery and transportation. They offer a cost-effective and efficient solution for various industries, enabling the reuse and repurposing of materials while minimizing environmental impact.

Contact For Our Expert

Find out which attachment & Excavator works best for you!

Yantai Jiangtu Showcases Quick Couplers and Grapples at CONEXPO CON/AGG 2026 | Booth C33096

Yantai Jiangtu will present its advanced excavator quick couplers and grapples at CONEXPO CON/AGG 2026, taking place March 3–7 at the Las Vegas Convention Center. As a leading excavator attachment…

Customer Satisfaction is Our Driving Force – The Story Behind the Hot-selling Tilt Quick Coupler From Yantai Jiangtu

Real feedback from our customer Recently, we received good news from overseas customers.“Yes, one unit sold, customer very happy, also I checked at his place, and no marks about using,…

Empowering Efficiency! JAINGTU Attachments Shine At The Lingong Customer Festival

Attend the event and witness the glory Recently, Lingong Customer Festival site is crowded, Yantai Jiangtu exhibition area is even more hot – a variety of perfectly matched with the…

Customers Praise Jiangtu Quick Coupler – The Rolls-Royce of Quick Coupler

In 2018, a customer purchased one set quick coupler from Yantai Jiangtu,suitable for his Doosan 210 excavator. After years of use, the customer gave it high praise ‘ I’ve been…

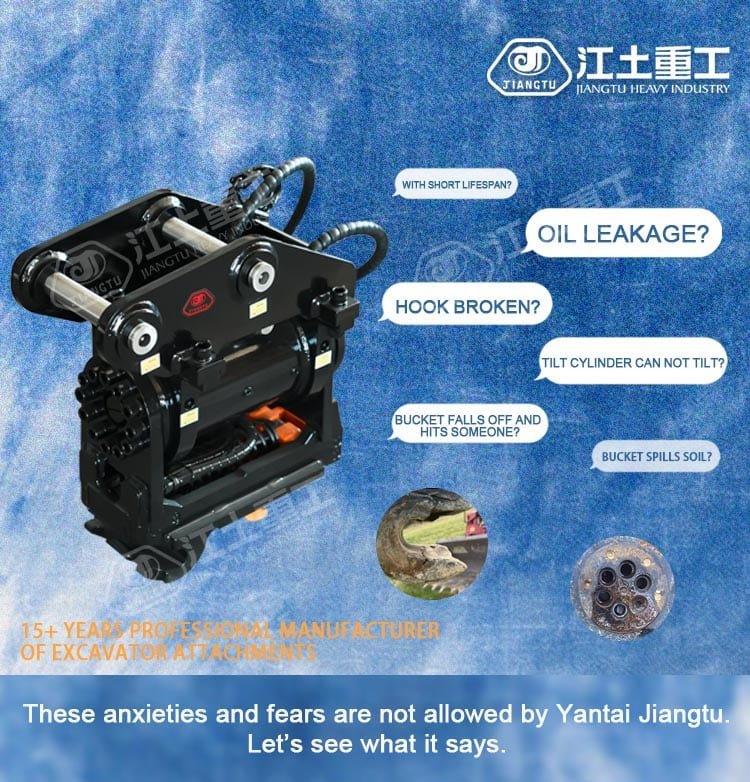

These Problems Are Not Allowed To Occur At All In Jiangtu Quick Coupler

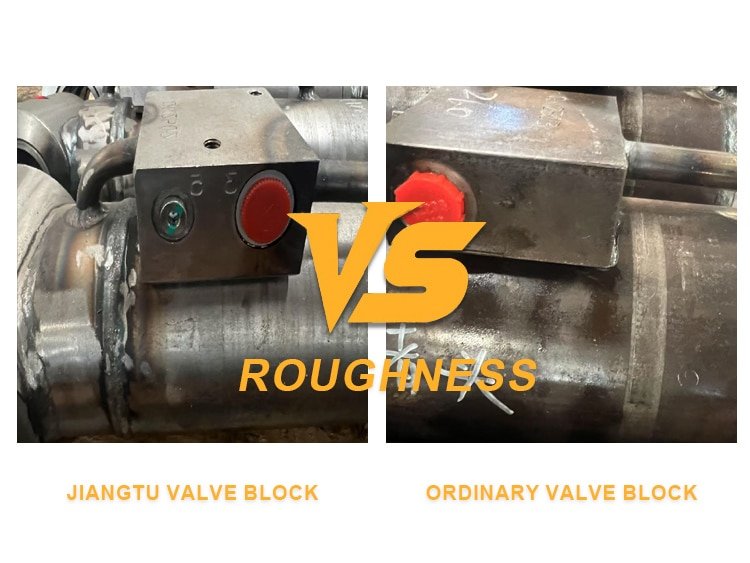

Some Quick Coupler Trouble These anxieties and fears are not allowed by Yantai Jiangtu. Let’s see what it says. Yantai Jiangtu Mechanical Equipment Company is a leading manufacturer of excavator…

Sany Group and Yantai Jiangtujointly held an engineering machinery and attachments exhibition

On June 30, Sany Group and Yantai Jiangtu Mechanical Equipment Co.,LTD jointly held a grand excavator and attachments exhibition in Kunshan city, showing the latest technological innovations and intelligent solutions in the field of…

Jiangtu 13th Anniversary Factory Celebration Ceremony Global Customer Appreciation Feedback

Since its establishment in 2012, Jiangtu has always been adhering to the core values of ‘quality-oriented, integrity-based, service-oriented’, focusing on the research and development and innovation of excavator quick couplers….

High Quality Cylinder Makes Excellent JIANGTU Quick Hitch Coupler

JIANGTU quick hitch coupler has always been famous for its “good quality and durable use”. Many customers initially chose other brands because of the price, but “the cheaper option” had frequent issues, and then,…